What is the difference between IBC solar cells and ordinary solar cells?

What is the difference between IBC solar cells and ordinary solar cells?

With the increasing interest in renewable energy, solar cells have become the focus of attention. In the field of solar cells, IBC solar cells and ordinary solar cells are the two most common types. So, what is the difference between these two types of cells?

The manufacturing process is different:

IBC solar cells use an interfingered back electrode structure, which can make the current in the cell more evenly distributed, thereby improving the conversion efficiency of the cell. Ordinary solar cells use the traditional method of extracting the positive and negative electrodes, that is, the positive and negative electrodes are made on both sides of the cell.

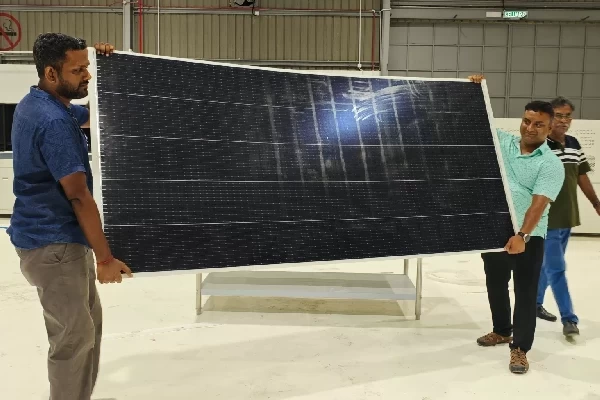

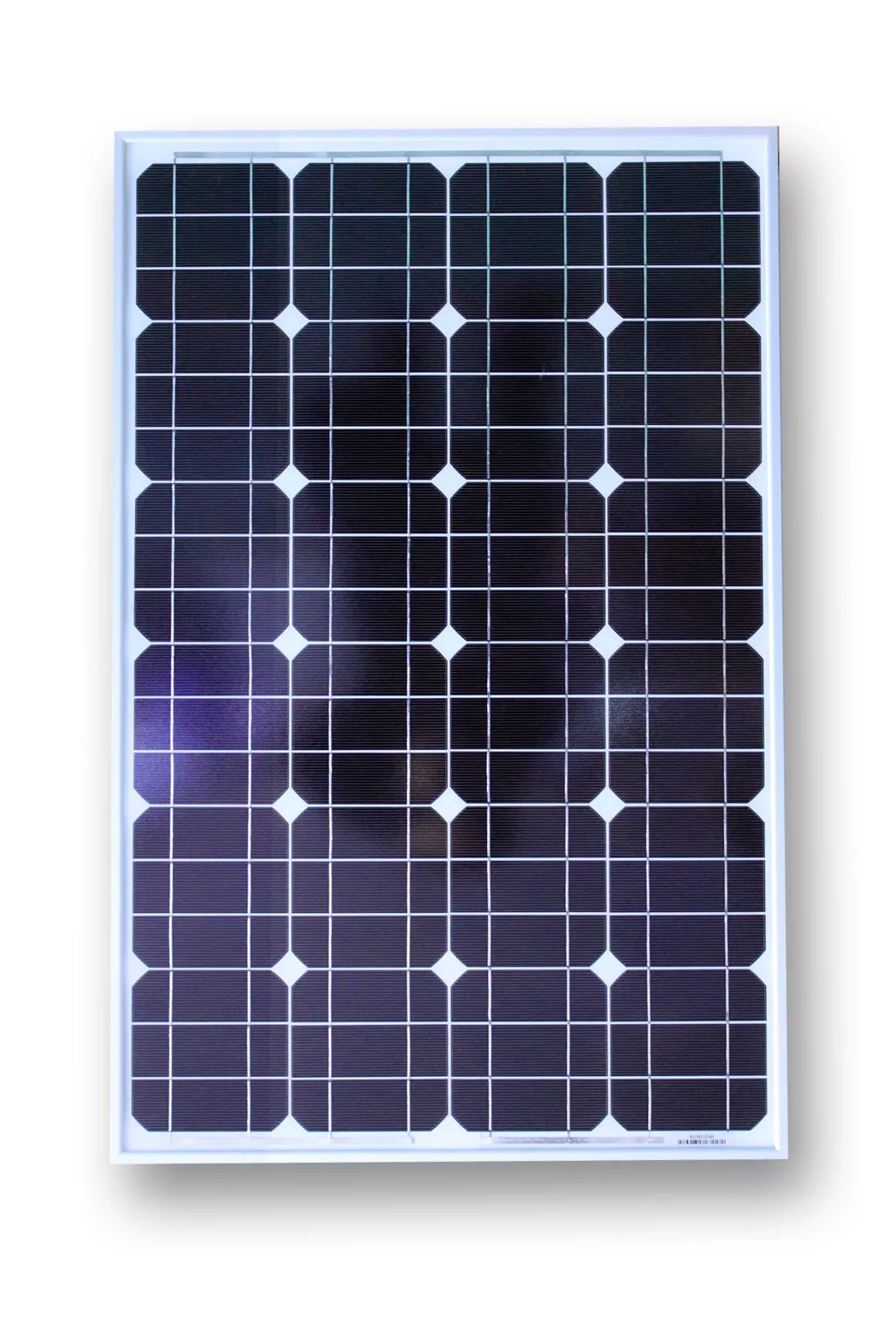

The appearance is different:

The appearance of the IBC solar cell presents a "fingerprint-like" pattern, which is caused by its cross-finger back electrode structure. The appearance of ordinary solar cells presents a "grid-like" pattern.

Performance is different:

Due to the different manufacturing process and appearance, there are certain differences in the performance of IBC solar cells and ordinary solar cells. IBC solar cells have high conversion efficiency, and their manufacturing costs are relatively high. The conversion efficiency of ordinary solar cells is relatively low, but its manufacturing cost is also relatively low.

The field of application is different:

Due to their high efficiency and high cost, IBC solar cells are often used in high value-added applications, such as aerospace, satellite communications, etc. Ordinary solar cells are more widely used in large-scale photovoltaic power stations and other fields.

To sum up, there are certain differences between IBC solar cells and ordinary solar cells in terms of manufacturing process, appearance, performance and application fields. The type of cell you choose depends on your specific application needs and budget.

Previous:The main differences between N-type and P-type monocrystalline silicon wafers for solar photovoltaic

cut cell to half, 1/3 1/4 1/5 1/6 1/7 1/8

Market Research Industry Learning

Non Destructive Cutting Machine Thermal Laser Separation Cutting Machine

solar strings busbar welding after layup

Workshop layout Production Design