5-10MW Annual Semi-Auto Solar Panel Production Line

5-10MW Annual Semi-Auto Solar Panel Production Line

Many customers want to open solar panel making plant, but they don’t know the manufacturing process and how to configure solar panel manufacturing equipment so the idea has never been realized.

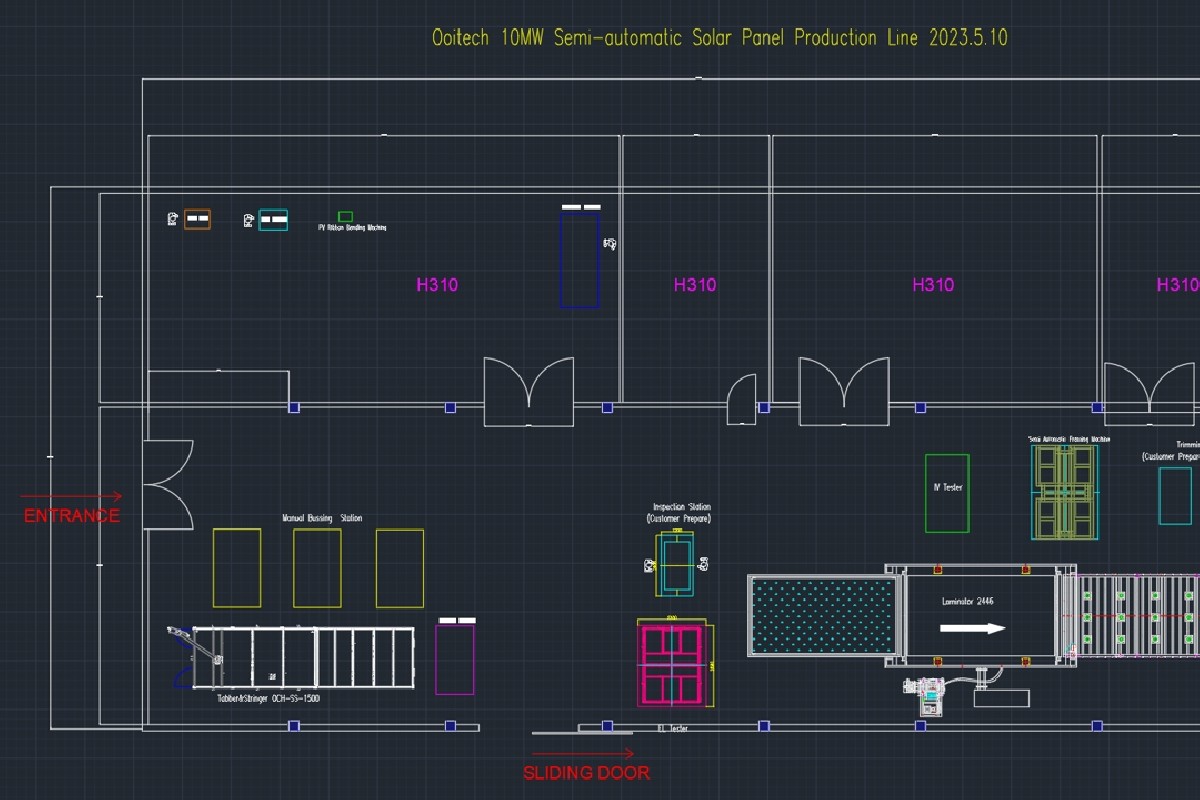

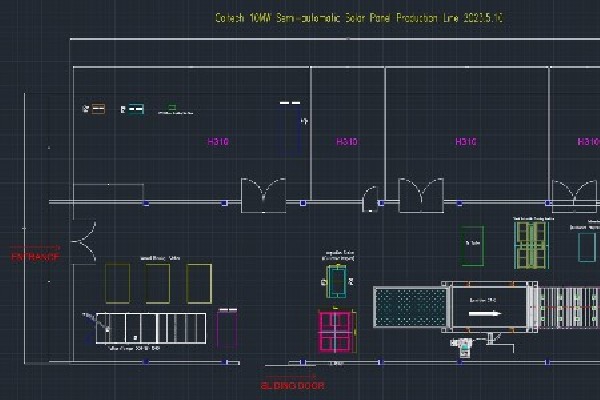

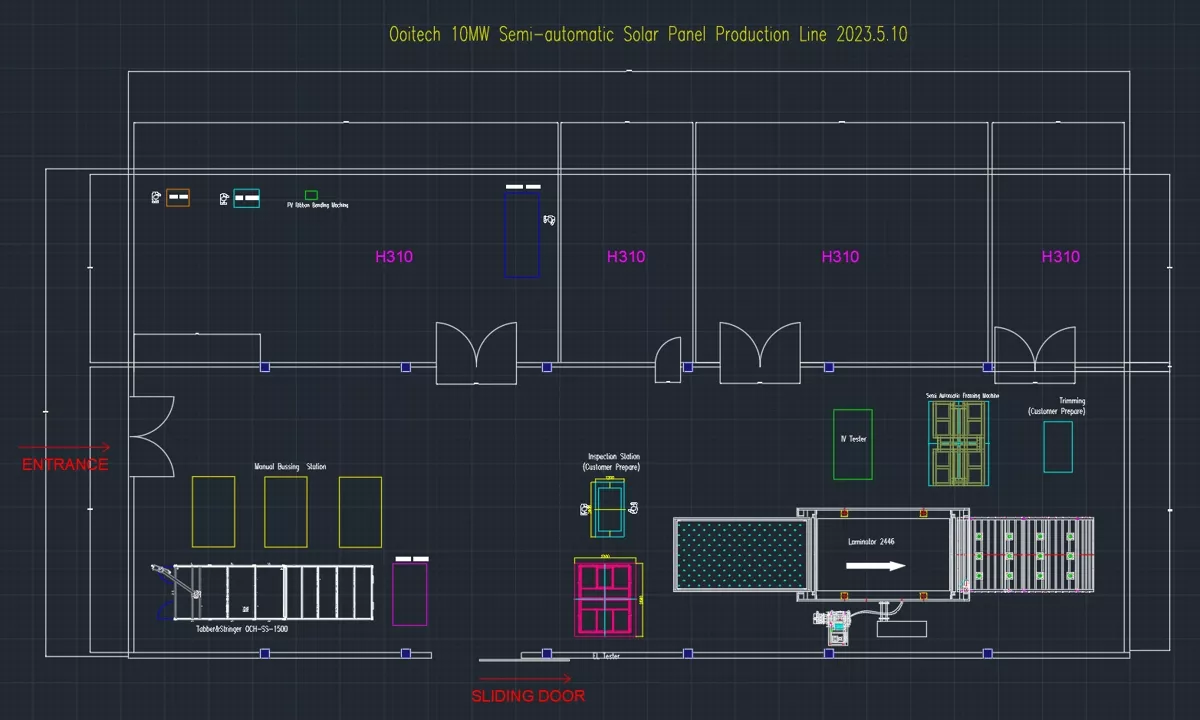

1. Factory Layout Drawing

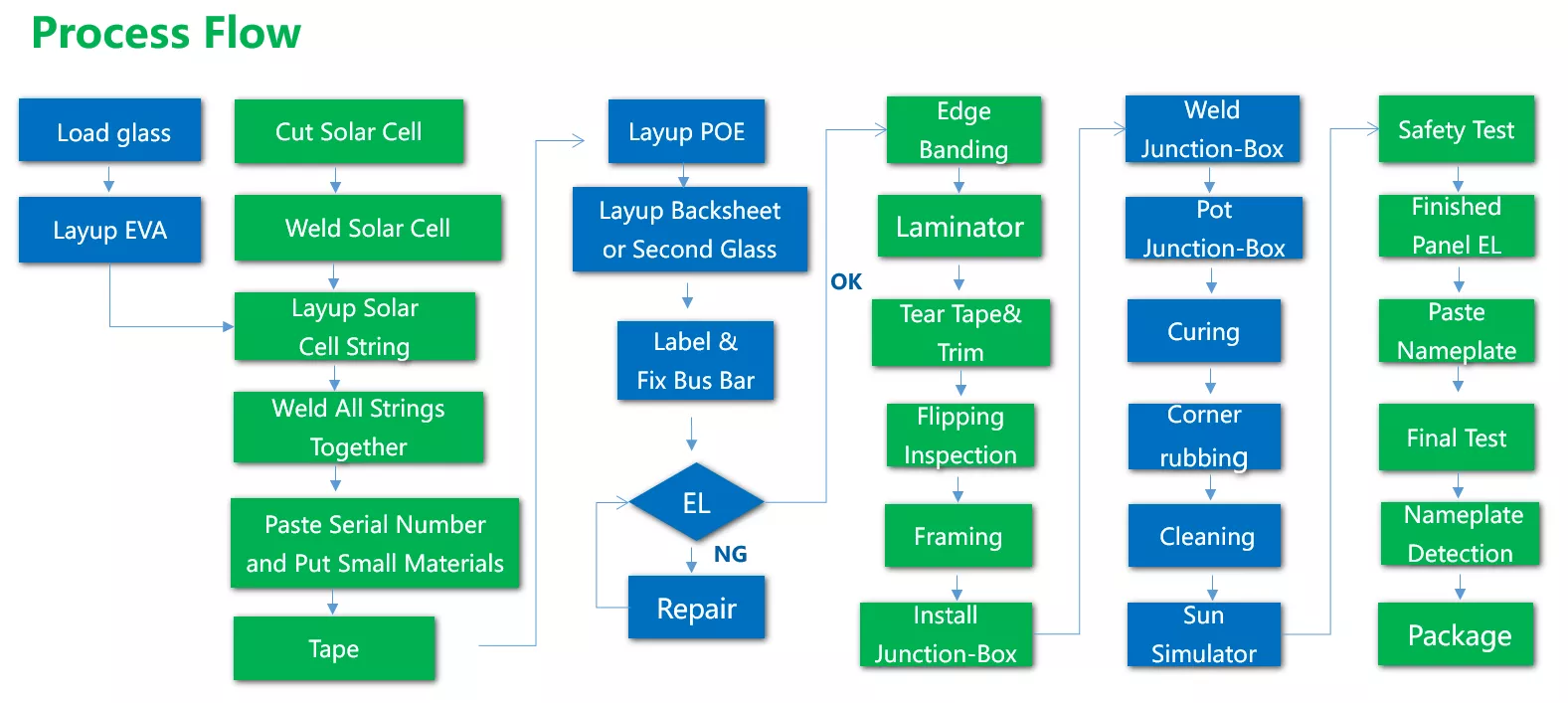

2. Mainly manufacturing process

Step 1: Test solar cell efficiency: make sure the same power cell to be used in one solar panel;

Step 2: Cut complete solar cell into small pieces;

Step 3: Welding solar cell: welding solar cell to string solar cell;

Step 4: Cutting EVA/TPT: according to the solar panel size to cut the EVA and TPT in the designed size;

Step 5: Lay up: achieve solar string automatic laying on glass EVA, and transporting module to the next process;

Step 6: Visual inspection: check the dirty for the Raw materials;

Step 7: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires, and other invisible defects in solar modules;

Step 8: Lamination: after EL tester checking the defects, use solar panel Laminate the raw material into solar panel;

Step 9: Trimming: when the Solar panel get cooling after coming out from laminator, It need Cutting the edges, we call Trimming;

Step 10: Glue: use sealant to glue up on aluminum frame;

Step 11: Framing: use the framing machine to install the aluminum frame;

Step 12: Glue: fill the sealant to aluminum alloy after framing;

Step 13: Install junction box: glue the junction box and install it on the solar panel;

Step 14: IV Test: use solar simulator to test the finished solar panel Electrical performance test like power, current etc and record;

Step 15: Test the panel withstand voltage insulation;

Step 16: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires and other invisible defects of finished solar modules;

Step 17: Label;

Step 18: Clean the surface and package.

3. Function & Picture of Main Machines of 5-10MW Annual Semi-Auto Solar Panel Production Line

Function:

Use to test the electrical performance of Mono-Si or Poly-Si solar cell pieces and record the results in files.

Picture:

Solar Cell Laser Cutting Machine

Function:

Scribing or cutting the Solar Cells and Silicon Wafers in solar PV industry, including the mono-si (mono crystalline silicon) and poly-si (poly crystalline silicon) solar cells and silicon wafer.

Picture

· MBB Solar Cell Tabber and Stringer

Function:

MBB PV Cell Soldering Stringer is used to weld the solar cells one by one through copper ribbon, and the cells are connected in series to form a string. The entire welding process is fully automated.

Picture:

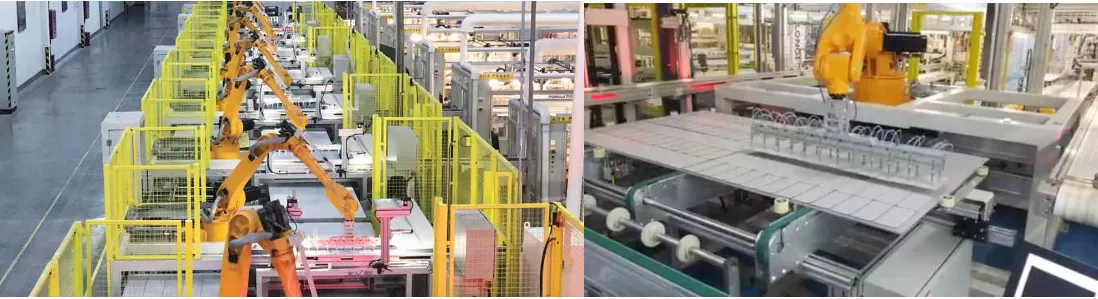

· Automatic Solar Cell String Lay Up Machine

Function:

Achieving solar string automatic laying on glass EVA, and transporting module to the next process

Picture:

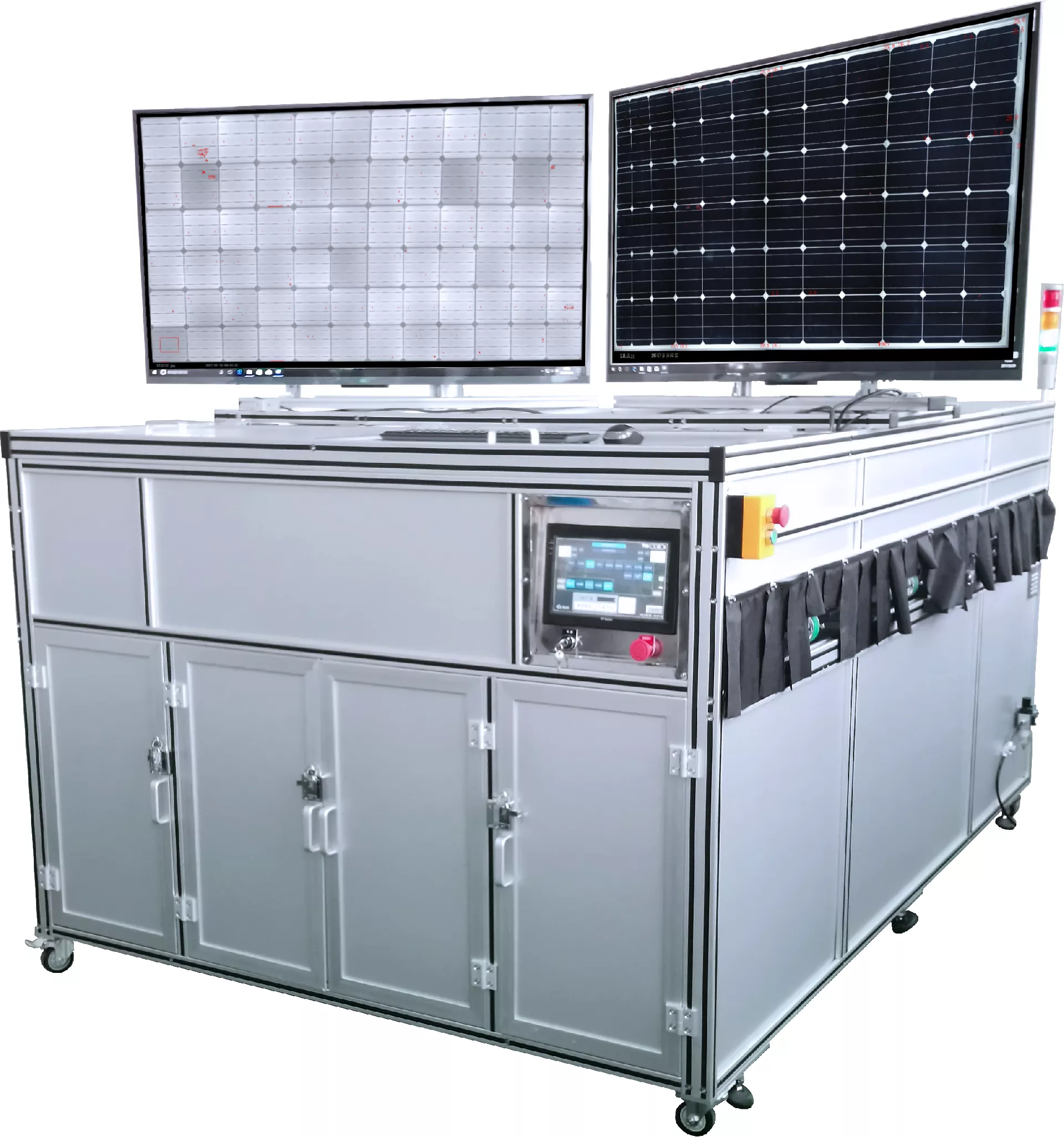

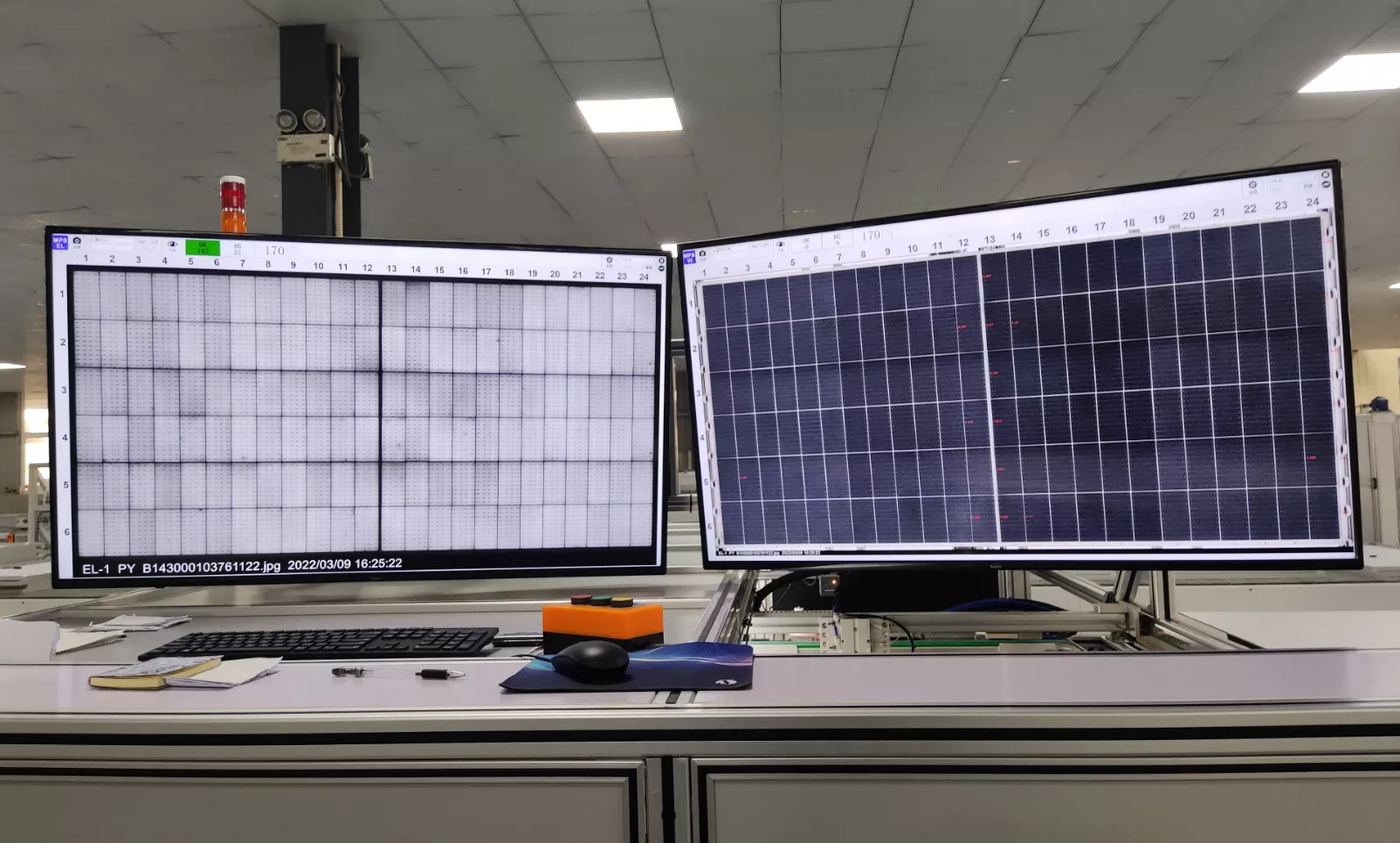

· Automatic PV Module EL Defect Tester with Visual Inspecting Function

Function:

Used in testing the solar cell crack,breakage, black spot,mixed wafers,process defect,cold solder joint phenomenon.

Picture:

· Automatic Solar Laminator

Function:

Solar panel laminator is a mechanical device that presses multiple layers of materials together.

Picture:

· Automatic Solar Panel Framing Machine

Function:

Automatic gluing & framing machine is used to install the aluminum frame and automatically overflow glue.

Picture:

· Automatic Solar Panel IV Tester

Function:

Automatic solar panel IV tester is used to test the electric performance of Mono-Si or Poly-Si solar modules and record the results in files .

Picture:

4. Packaging and transportation of 5-10MW Annual Semi-Auto Solar Panel Production Line

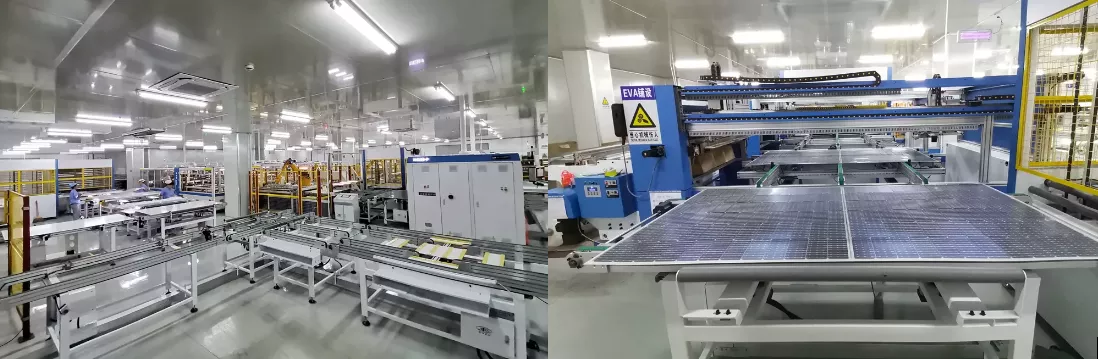

5. Case of 5-10MW Annual Semi-Auto Solar Panel Production Line