Introduction to OSLB-1300 BC String Welding Machine

Introduction to OSLB-1300 BC String Welding Machine

Introduction

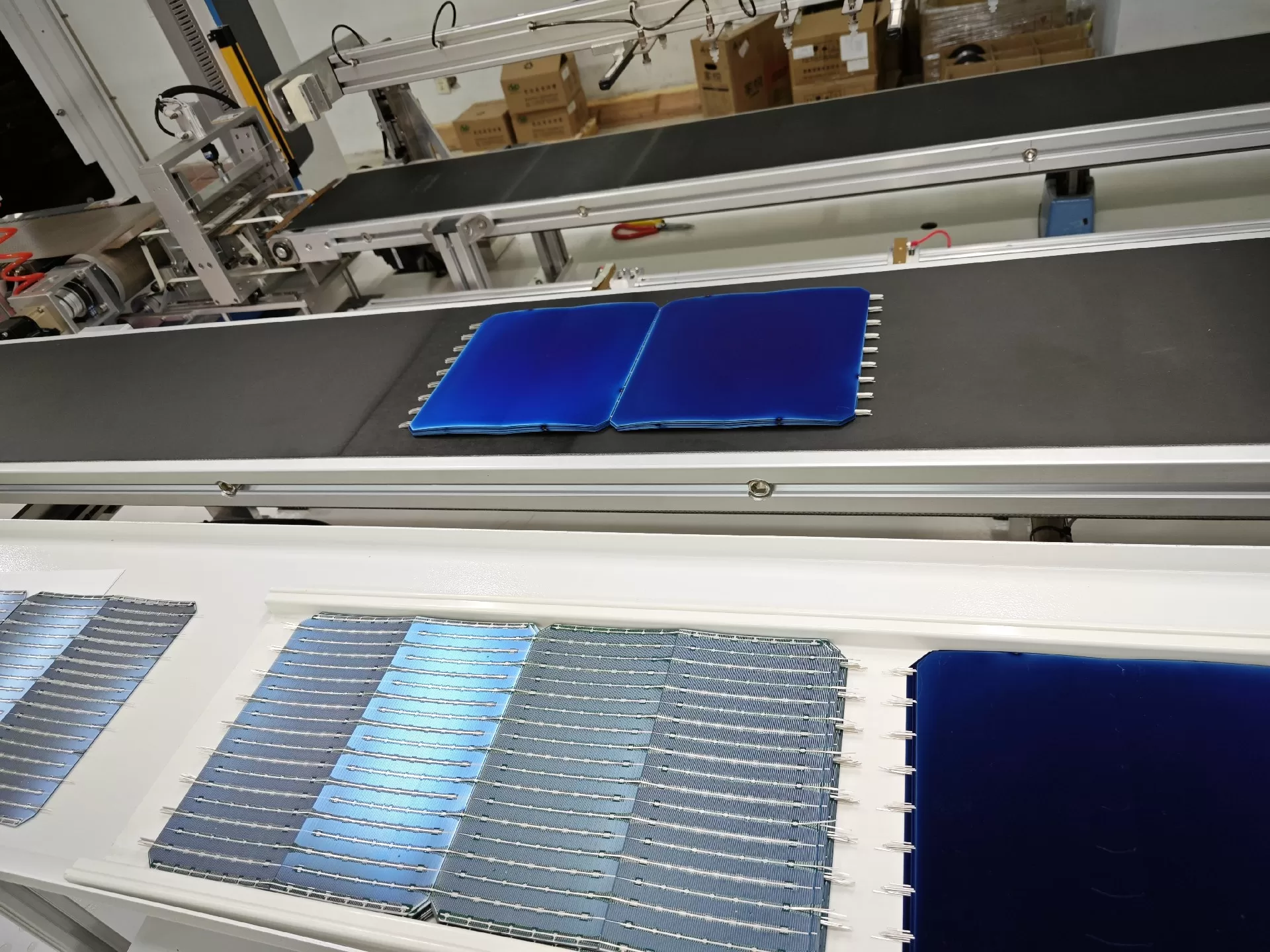

With the continuous development of photovoltaic technology, Back Contact (BC) battery technology has gained widespread attention as an efficient battery technology. BC batteries place all electrodes on the back of the battery, avoiding shading from front electrodes, which enhances the photoelectric conversion efficiency. The OSLB-1300 BC String Welding Machine introduced in this document is not only suitable for welding BC series battery strings but also compatible with various battery types such as Multi-Busbar (MBB), Passivated Emitter and Rear Cell (PERC), Tunnel Oxide Passivated Contact (TOPCon), and Heterojunction with Intrinsic Thin-layer (HJT).

2. Background on BC Battery Cells

2.1 Longi HPCB

Longi's High-Performance Back Contact Battery (HPCB) is a highly efficient BC battery technology. It features advanced battery structure design and processes that ensure high photoelectric conversion efficiency and reliability. HPCB batteries reduce costs while improving performance, providing a new impetus for the development of the photovoltaic industry.

2.2 Aiko ABC

Aiko's All-Back-Contact (ABC) battery is an entire back contact battery technology. It achieves high conversion efficiency and low degradation through its unique battery structure and processes. ABC batteries maintain stable performance under different lighting conditions, making them a competitive BC battery technology with high open-circuit voltage and fill factor.

2.3 Yellow River Hydropower IBC

Yellow River Hydropower's Interdigitated Back Contact (IBC) battery employs a unique electrode structure and process to enhance short-circuit current and fill factor. IBC batteries improve efficiency while reducing production costs, representing a promising BC battery technology with significant development potential.

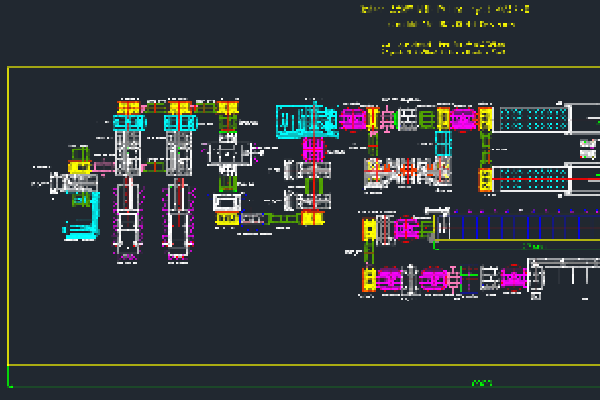

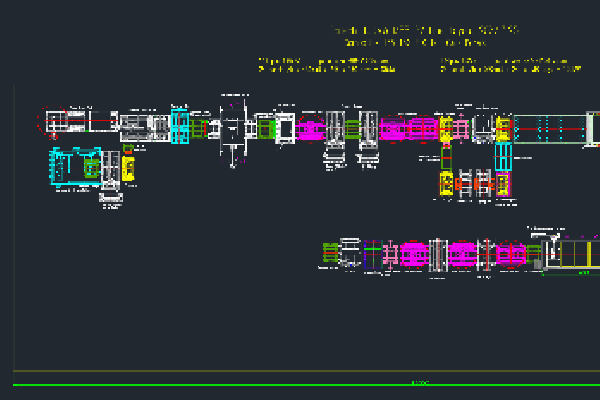

3. Equipment Overview

3.1 Basic Description

The OSLB-1300 BC String Welding Machine consists of several key components, including:

A/B double battery feeding trays

A/B soldering/glue application control system

Feeding transfer robotic arm

Battery transfer table

Battery flipping device

CCD + four-axis robotic detection and positioning system

Ribbon processing mechanism

Welding transfer table

Infrared temperature control heating system

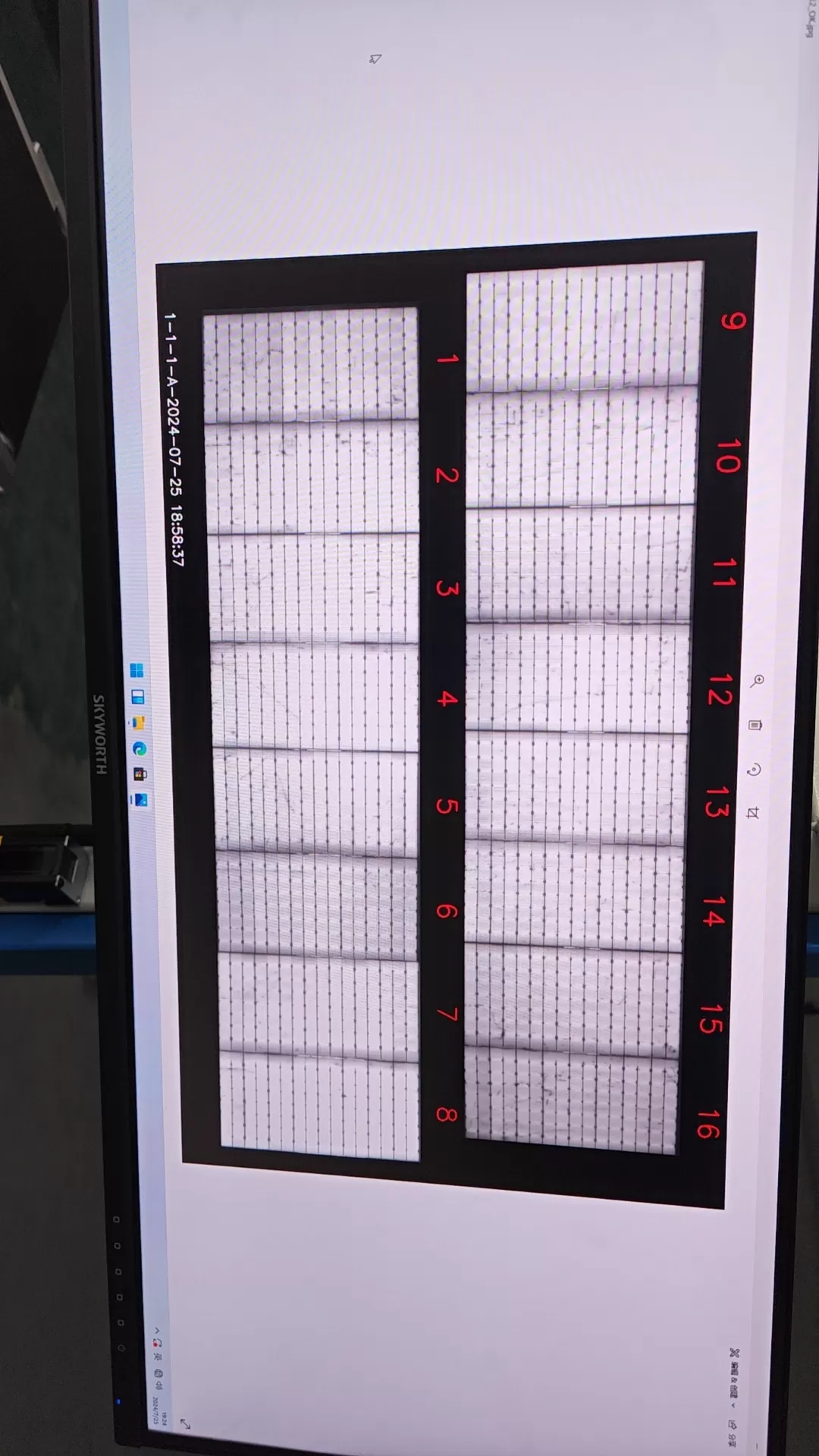

String EL detection system

Discharge mechanism

The working principle involves the robotic arm picking the battery cells from the feeding trays, followed by soldering/gluing, detection and positioning, ribbon processing, and placement. Finally, welding occurs on the welding transfer table, and discharge is handled by the discharge mechanism.

3.2 Applicable Battery Technologies

The equipment is specifically optimized for BC series battery strings, meeting the welding requirements for HPBC, IBC, ABC, XBC, and others, including Longi HPCB, Aiko ABC, and Yellow River Hydropower IBC. Moreover, the machine supports various battery types such as MBB, PERC, TOPCon, HJT due to its flexible feeding system, high-precision detection and positioning system, and adjustable welding parameters.

4. Equipment Hardware Specifications

4.1 System Composition

| Component | Description |

|---|---|

| A/B Double Tray | High-precision dual-position platform for feeding and soldering/gluing, adjustable for battery sizes below 210 mm. |

| Feeding Transfer Arm | Servo motor-driven, utilizing a rail-type belt module with high vacuum suction cups. |

| Battery Transfer Table | Driven by a servo motor + reducer, equipped with pre-positioning mechanisms. |

| Battery Flipping Mechanism | Driven by a servo motor + reducer, using silicone vacuum suction cups. |

| CCD + Four-Axis Robotics | SCARA four-axis robot with 800W pixel industrial camera; positioning accuracy ±0.15 mm. |

| Welding Transfer Table | Servo motor + reducer-driven with Teflon belt transfer; temperature control for different zones. |

| Infrared Heating Module | Comprising high-precision temperature control modules and infrared lamps. |

| Ribbon Processing Mechanism | Includes 10 sets of unwinding and detection mechanisms. |

| EL Detection System | Three-camera system with maximum string length detection of 1800 mm. |

| Discharge Mechanism | Features a PU belt-driven discharge conveyor. |

| Software Control System | Proprietary software for easy upgrades and friendly user interface. |

| Base Frame | Steel frame structure. |

4.2 Major Components List

Steel Frame: Q235 steel for the structure.

PLC: Huichuan/QT550 for system control.

Proximity Switches: OMRON series for arm positioning.

Pneumatic Components: AIRTAC/SMC series for the overall system.

Electrical Switches: CHINT series for control systems.

Servo Motors: Huichuan/Xinjie series for X/Y modules.

Touch Screen: Kunlun Tongtai/Huichuan 16-inch for system control.

Guide Rails and Screws: WON 16-inch for X/Y modules.

Four-Axis Robot: Chinese 600SR for cell grabbing and positioning.

Camera: Hikvision/Dahua for CCD detection.

Infrared Welding Lamp: Custom-made in China for soldering cells and ribbons.

5. Equipment Technical Parameters

| Parameter | Value |

|---|---|

| Production Capacity | ≥1000 PCS/H |

| Positioning Accuracy | ±0.10 mm |

| Maximum Operating Speed | Adjustable up to 1000 mm/s |

| Applicable Cell Size | 166210*30166 mm |

| Maximum String Length | 1800 mm |

| Welding Method | Ribbon welding |

| Soldering/Glue Application Systems | 2 sets |

| Cell Detection | CCD camera detection (corner detection) |

| Placement Accuracy | ±0.2 mm |

| Coating Medium | Solder paste or conductive glue (based on customer's welding process) |

| Cell Breakage Rate | ≤0.2% (Grade A cells) |

| Equipment Failure Rate | ≤3% |

| Loading/Unloading Method | Automatic |

| Electrical System | PLC + Touch Screen + Servo + Module |

| Human-Machine Interface | Touchscreen with user-friendly operation |

| Fault Alarm | Real-time fault alerts |

| Equipment Color | Main body white |

6. Summary of Equipment Advantages

6.1 High Precision

The machine ensures high precision during cell grabbing, positioning, and welding processes, with positioning accuracy reaching ±0.10 mm and placement accuracy of ±0.2 mm, ensuring the quality of the battery strings.

6.2 Strong Compatibility

The OSLB-1300 is compatible with various BC technologies, including Longi HPCB, Aiko ABC, Yellow River Hydropower IBC, and can also accommodate MBB, PERC, TOPCon, and HJT battery types, providing flexible production options for photovoltaic enterprises.

6.3 High Efficiency and Stability

With a production capacity of ≥1000 PCS/H and a failure rate of ≤3%, this equipment meets the needs for large-scale production while ensuring stability during the manufacturing process.

6.4 Intelligent Features

Equipped with a proprietary software control system, the machine has a user-friendly interface for easy parameter setting and trajectory editing. It also provides real-time fault alerting, facilitating maintenance and management.

For more information about our solar production equipment, please visit our YouTube channel and check out our MBB Full Automatic Solar Panel Production Line video. You can also download our catalog here and learn more about our company here. For inquiries, contact us at [email protected] or via WhatsApp at +8615961592660.