What is a HJT solar cell?

For many years, heterojunction (HJT) technology was overlooked, but it has gained traction in recent years, demonstrating its real potential. Ordinary photovoltaic (PV) modules address some of the most prevalent limitations of ordinary photovoltaic (HJT) modules, such as lowering recombination and boosting performance in hot regions.

This article is for you if you want to learn more about HJT technology.

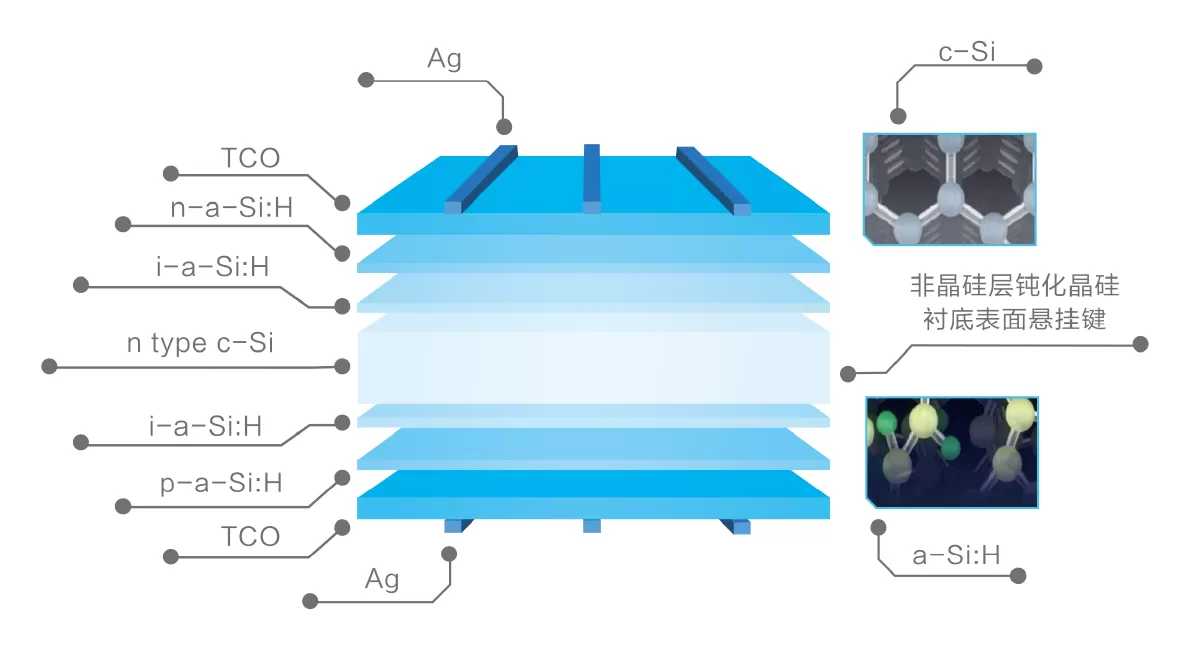

HJT Solar Cell Based on N-type Silicon Wafer

As a mature solar cell technology, heterojunction technology has been proved to deliver higher efficiency, better performance, and durability.

The manufacturing process of an HJT Cell is more efficient and taking less step compare with other cell processing technology.

HJT solar cell is also a natural bifacial cell, with much better stable solar cell color.

What Does HJT Solar Cell Mean?

HJT is Hetero-Junction solar cells. As of the time of writing, HJT is a prospective successor to the popular PERC solar cell and other technologies like PERT and TOPCON. Sanyo first introduced it in the 1980s and was later bought by Panasonic in the 2010s.

This design could make using existing solar cell production lines that use PERC technology easier because the HJT has a much smaller number of cell processing stages and a much lower cell processing temperature than the PERC.

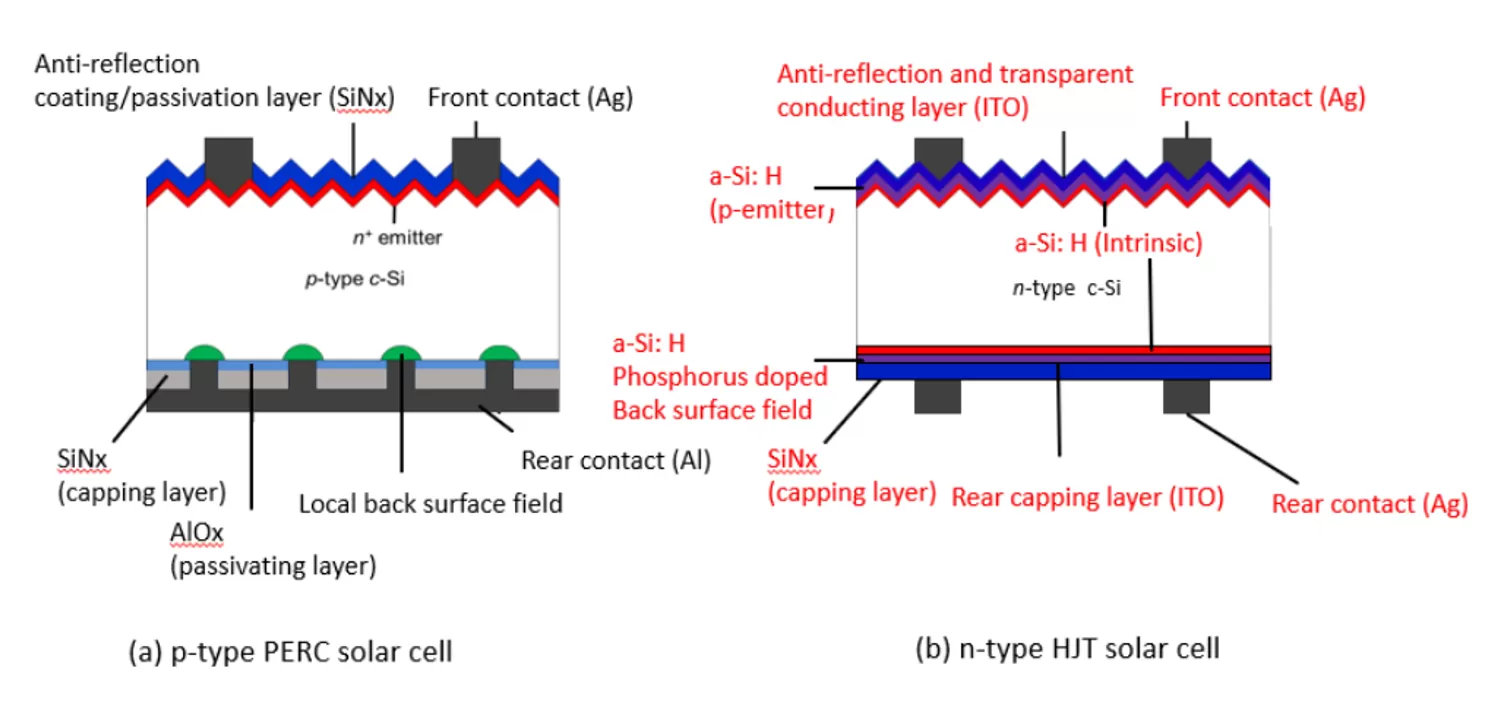

Figure 1: PERC p-type vs. HJT n-type solar cell.

Figure 1 shows how HJT differs from the common PERC structure. As a consequence, the production methods for these two topologies vary dramatically. Unlike n-PERT or TOPCON, which can be modified from existing PERC lines, HJT needs a lot of money to buy new equipment before it can start making a lot of money.

Furthermore, like with many new technologies, HJT's long-term operation and manufacturing stability is currently being investigated. This is owing to processing issues, including amorphous Si's sensitivity to high-temperature procedures.

How Does HJT Work?

Under the photovoltaic effect, heterojunction solar panels function similarly to conventional PV modules, with the exception that this technology employs three layers of absorbing materials, integrating thin-film and standard photovoltaic technologies. In this example, we'll connect the load to the module, and the module converts the photons into electricity. This electricity flows through the load.

When a photon strikes the P-N junction absorber, it excites an electron, which causes it to migrate to the conduction band and form an electron-hole (e-h) pair.

The terminal on the P-doped layer picks up the excited electron, which causes electricity to flow through the load.

After passing through the load, the electron returns to the cell's rear contact and recombines with a hole, bringing the e-h pair to a close. As the modules create power, this happens all the time.

A phenomenon known as surface recombination restricts the efficiency of conventional c-Si PV modules. These two things happen at the surface of a material when an electron is excited. They can then recombine without the electron being taken and flowing as an electric current.

Is the HJT Solar Cell Efficient and Reliable?

Due to excellent hydrogenated intrinsic amorphous Si (a-Si:H in Figure 1) that may give excellent defect passivation to both the back and front surfaces of Si wafers, HJT exhibits exceptional solar cell efficiency (both p-type and n-type polarity).

ITO as transparent contacts enhances current flow while simultaneously functioning as an anti-reflection layer for improved light capture. Another way to put ITO down is to do it through sputtering at low temperatures, which will keep the amorphous layer from re-crystallizing. This would make the bulk Si surface less passivating for the materials that are on it.

Despite its processing problems and expensive initial costs, HJT remains a popular technology. In comparison to TOPCON, PERT, and PERC technologies, this technique has shown the capacity to produce > 23% solar cell efficiency.

Machines for HJT Solar Panel?

the machines for HJT solar Panel making almost same as normal solar panel making machines, but few machines different

for example: HJT solar cell tabber stringer, HJT solar cell tester, and HJT solar panel laminator.

and rest machines almost same as normal, form our one stop solutions we could provide all machines for HJT solar panels

electric heating type and oil heating type available for all size solar cells

welding half-cut solar cells from 156mm to 230mm