HPBC ABC XBC IBC Tabber Stringer Back Contact Back Contact Cell Welding Machine

HPBC ABC XBC IBC Tabber Stringer Back Contact Back Contact Cell Welding Machine

Machine Function

Back Contact Tabber Stringer is suitable for welding BC series cell strings.

Technical Parameter

Model | OSLB-1300 |

Capacity | ≤1000PCS/H |

Positioning accuracy | ±0.10mm |

Maximum operating speed of the device | 1000mm/s Adjustable |

Applicable cell size | 166~210*30~166mm |

Maximum string length | 1800mm |

Welding method | Gluing+ribbon welding |

Gluing system | 2 sets |

Cell detection | CCD camera detection (missing angle) |

Placing accuracy | ±0.2mm |

Spray media | Solder paste or conductive glue (based on customer's welding process) |

Cell fragmentation rate | ≤0.2%(Class A cells) |

Equipment failure rate | ≤3% |

Loading and unloading method | Automatic loading and unloading |

Electrical system | PLC+Touchscreen+Servo+module |

HMI | Touch screen, friendly interface and easy operation |

Error alarm | Real-time fault alarm |

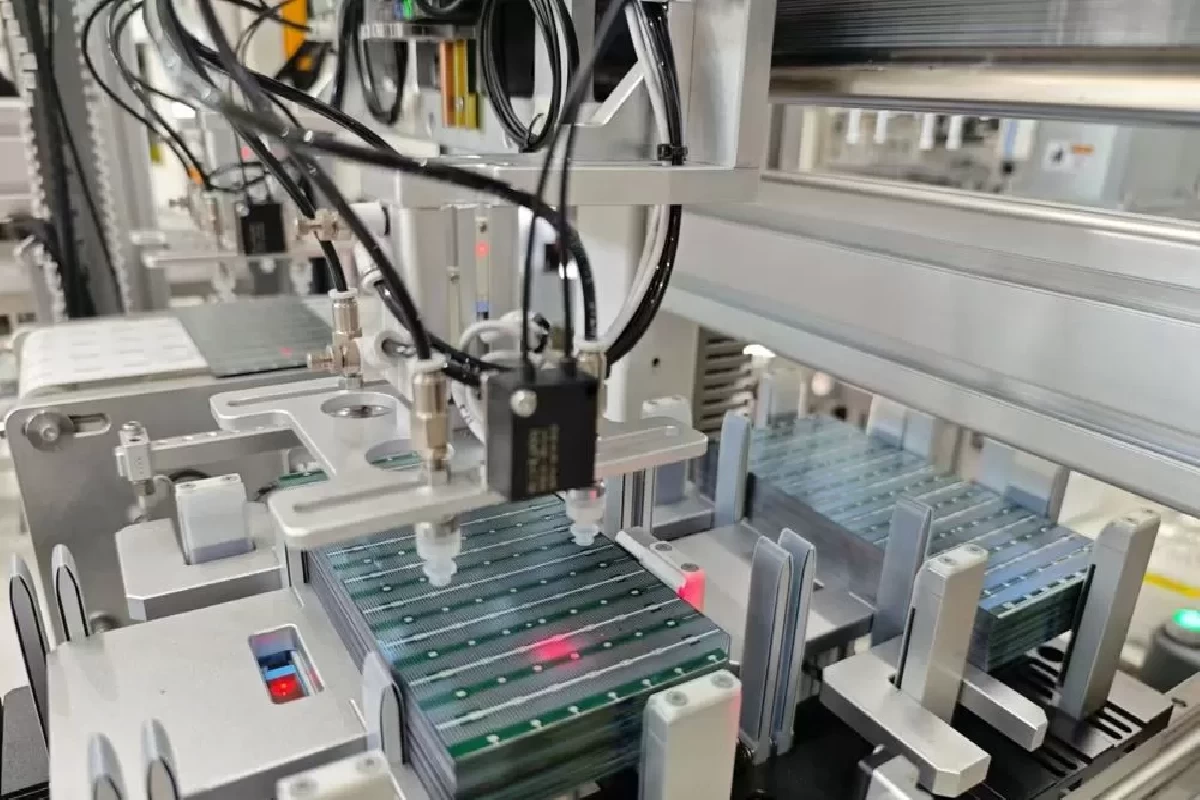

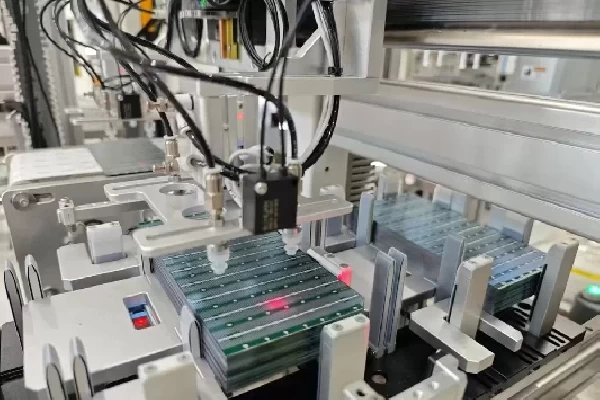

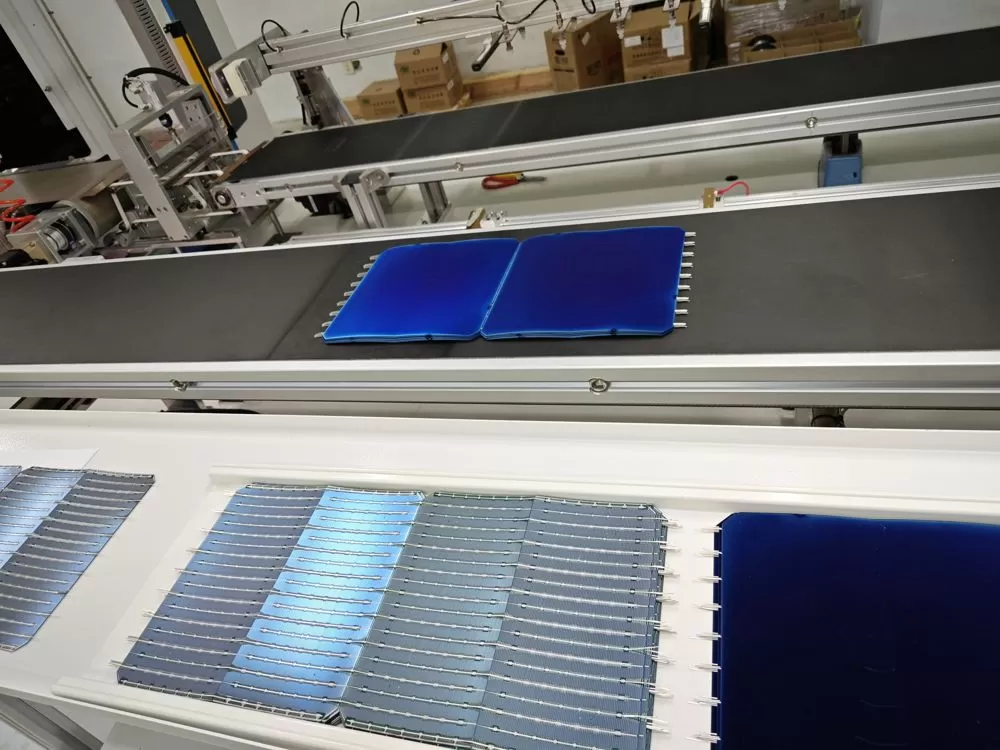

Detail picture

BC Solar Cell Technology (Back Contact Solar Cell Technology)

BC solar cell technology, also known as Back Contact Solar Cell Technology, is an advanced photovoltaic technology. Unlike traditional solar cells, BC cells have both the positive and negative electrodes on the back of the cell. This design eliminates the front-side grid lines that block sunlight, leading to improved energy conversion efficiency.

Key advantages of BC solar cell technology:

Higher efficiency: With the electrodes located on the back, there are no grid lines on the surface blocking light, allowing the cell to absorb more sunlight and improve energy conversion.

Aesthetic appearance: The absence of metal grid lines on the front makes the surface more visually appealing, which is especially important for applications like Building-Integrated Photovoltaics (BIPV).

Lower series resistance: Since the current flows from the back, it reduces the power loss due to current resistance in the electrodes, enhancing overall efficiency.

Improved reliability: The back-contact structure reduces thermal stress and uneven heating on the cell, resulting in higher reliability and longer lifespan.

BC Stringer Machine (Back Contact Stringer Machine)

A BC stringer machine is a specialized piece of equipment used for soldering BC solar cells together in series to form a complete solar module. It utilizes advanced automation to precisely connect the solar cells, ensuring consistent electrical performance and efficiency.

Features of BC stringer machines:

High-precision soldering: The machine is capable of accurately positioning and soldering the back-contact solar cells, ensuring low resistance and durable connections.

High automation: BC stringer machines are typically equipped with advanced automation systems that significantly reduce manual labor and improve production efficiency.

Designed for BC cells: The machine is specifically designed to handle the unique back-contact structure of BC cells, ensuring that the soldering process does not affect the photovoltaic performance of the cells.

Fast soldering speed: Utilizing high-speed series soldering technology, the machine can connect a large number of cells in a short amount of time, boosting production throughput.

The combination of these technologies enhances the overall performance and aesthetics of solar modules while significantly improving manufacturing efficiency in the photovoltaic industry.