How to Make Half-cut Solar Panels by Half-cut Solar Cells

- What is half-cut solar cell technology

- What is a half cell solar panel and how does it work?

- Advantages of Half-cut cells

- How may kind of half-cut solar module

- How to make half-cut solar cells

- How to make half-cut solar module

- Machines that make half-cut panels

- Can half-cut panels be made manually

- Full-auto produce line of hall-cut panels

How to make half-cut solar panels by half-cut solar cells

In the solar industry, Solar energy has become increasingly popular in recent years as people have become more aware of its benefits. Solar energy is a renewable source of energy that comes from the sun, and it is environmentally friendly and sustainable.

The advantage of half-sheet solar cells is they are smaller than whole cells. A sheet of half-cells can be cut in two and mounted on the top and bottom of a module, then wired together with each other to form a complete circuit. Half-cut modules typically have higher efficiency than full-size modules because there is less heat loss due to the larger surface area. The equipment needed for the manufacturing process includes:

1) solar cell cutting machine

2) Module production line

3) solar panel test machine

and here we have followed contents about this subject

1, What is half-cut solar cell technology?

Compare with traditional solar panels, half-cut solar cells are a relatively new technology in the world of solar energy. They are created by cutting a standard solar cell in half. This is made possible by using two half-cut cells in series instead of one full-sized cell.

Half-cut solar cells are a type of solar cell that has been cut in half, with the two halves then being joined back together. This allows for the use of two smaller solar cells in place of one larger solar cell, which can be advantageous in some cases. For example, using two smaller solar cells can make it easier to fit them into a more compact space, or it can make them less heavy and therefore easier to transport.

2, What is a half cell solar panel and how does it work?

In a traditional silicon cell-based PV module, the ribbons interconnecting neighboring cells can cause a significant loss of power during the current transport. Cutting solar cells in half has been proven to be an effective way to lower resistive power loss.

The half-cut cells generate half the current of a standard cell, reducing resistive losses in the interconnection of solar modules. Less resistance between the cells increases the power output of a module. Solar Power World Online has noted half-cut cells can potentially boost power output between 5 to 8 W per module, depending on the design.

With a higher power output on a module that costs relatively similar, it speeds up ROI. This makes the cells a great idea for end users who want a quicker turnaround on their investment.

After conducting a series of tests of half-cut and PERC solar cells in a large-area PV module in a controlled environment, the Institute for Solar Energy Research Hamelin broke the previous record for module efficiency and peak output, PV-Tech reported. While they're not the only organization performing ground-breaking work on half-cut cells, the record, which was independently confirmed by TUV Rheinland, demonstrates the viability of using these modules to bring PV development to its most advanced and lowest cost yet.

Because of its performance gains, many companies have already switched to half-cut designs, which should further increase the market share for these PV products.

Half-cut solar cell technology increases the energy output of solar panels by reducing the size of the cells, so more can fit on the panel. The panel is then split in half so the top operates independently of the bottom, which means more energy is created - even if one half is shaded.

That’s the general overview - below, we break the process down.

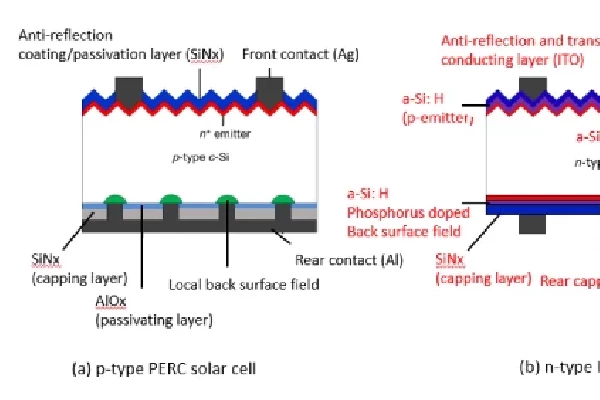

Traditional monocrystalline solar panels usually have 60 to 72 solar cells, so when those cells are cut in half, the number of cells increases. Half-cut panels have 120 to 144 cells and are usually made with PERC technology, which offers higher module efficiency.

The cells are cut in half, very delicately, with a laser. By cutting these cells in half, the current within the cells is also halved, which essentially means that resistive losses from traveling energy via current are reduced, which, in turn, equals better performance.

Since the solar cells are cut in half and are thereby reduced in size, they have more cells on the panel than traditional panels do. The panel itself is then split in half so that the top and bottom portions operate as two separate panels - generating energy even if one half is shaded.

The key to half-cut cell design is a different method of “series wiring” for the panel or the way the solar cells are wired together and pass electricity through a bypass diode within a panel. The bypass diode, indicated by the red line in the images below, carries the electricity that the cells generate to the junction box.

In a traditional panel, when one cell is shaded or faulty and does not process energy, the entire row that is within the series wiring will stop producing power.

For example, let’s take a look at the traditional solar panels 3-string series wiring method :

solar panels wired in series

With the traditional full cell string series wiring, shown above, if a solar cell in Row 1 does not have ample sunlight, every cell within that series will not produce energy. This knocks out a third of the panel.

A half cells, 6-string solar panel works a bit differently:

half cut solar cell

If a solar cell in Row 1 is shaded, the cells within that row (and that row only) will stop producing power. Row 4 will continue to produce power, generating more energy than a traditional series wiring because only one-sixth of the panel has stopped producing power, instead of one-third.

You can also see that the panel itself is split in half, so there are 6 total cell groups instead of 3. The bypass diode connects in the middle of the panel, instead of on one side like the traditional wiring above.

3, Advantages of Half-cut cells

Here, we listed several ways to show how half-cut cells improve panel performance. 1. Reduce resistive losses One source of power loss when solar cells convert sunlight into electricity is resistive losses or power lost during electrical current transport. Solar cells transport current using the thin metal ribbons that cross their surface and connect them to neighboring wires and cells and moving current through these ribbons leads to some energy loss. (Sources: EnergySage) By cutting solar cells in half, the current generated from each cell is halved, and the lower current flowing leads to lower resistive

Half-cut cell technology is now popular in solar panel manufacturers factories, like Trina, Suntech, Longi, and jingko solar, and also in mass production all over the world. more than 50% of the capacity of the production line in China now updates traditional solar cells to manufacturing half-cut cell solar panels.

The benefits of Half-Cut solar cell technology include:

Higher Efficiency: when a solar cell is cut in half, the amount of electrical current that is carried by each busbar is also reduced by half. This decrease in resistance within the busbars causes an overall increase in its efficiency. For the LONGi system, the equates to a power increase in the module of 2%. This is significant of half-cut cell technology

Lower Hot Spot Temperature: hot spots in the module can cause irreversible damage to the cells. Reduction of hot spot temperatures of between 10-20°C improves the reliability of the module.

Lower Operating Temperature: reduces thermal loss and improves both module reliability and power gain.

Lower Shading Loss: half-cut modules can still achieve 50% output during shading, including sunrise and sunset conditions.

nowadays more and more solar panel manufacturers start to make half cell solar panels.

4, how many kinds of half-cut solar module

Half-cut cell modules have solar cells that are cut in half, which improves the module’s performance and durability. Traditional 60- and 72-cell panels will have 120 and 144 half-cut cells, respectively. When solar cells are halved, their current is also halved, so resistive losses are lowered and the cells can produce a little more power. Smaller cells experience reduced mechanical stresses, so there is a decreased opportunity for cracking. If the bottom half of a module is shaded, the top half will still perform.

Traditional full cell panels ( 60 cells) are made with 60 or 72 cells on the entire panel. A half-Cell module doubles the number of cells into 120 or 144 cells per panel. The panel is the same size as a full cell panel but with double the cells. By doubling the number of cells this technology creates more avenues to catch energy from sunlight to send into the inverter.

Essentially, Half-Cell technology is the process of cutting cells into half, reducing resistance so efficiency can increase. Traditional full cell panels with 60 or 72 cells produce resistance which can lower the panel’s ability to produce more power. Whereas Half-Cells with 120 or 144 cells have lower resistance which means more energy is being captured and produced. Half-Cell panels have smaller cells on each panel which reduces mechanical stresses on the panel. The smaller the cell the lesser chance of the panel micro cracking.

Moreover, Half-Cell technology provides higher power output ratings and is usually more reliable than traditional full cell panels.

120 half cell solar panel 144 half cell solar panel and 132 half cell solar panel

158.78 166 182 210

different half-cut solar panels applications, depending on solar panel system requirements. for example, land solar farms usually like half cell panels

5, how to make half-cut solar cells

by solar cell cutting machine to make half-cut solar cells, and here we have auto split cells solar cell cutting machine, and manually split half-cut cells

solar cell cutting (scribing) machine not only cut solar cells to half but also can cut 1/3 1/4 1/5 1/6 1/7 even smaller, and also can cut shingled solar panels

traditional half-cut cell solar cutting machine:

2021 Solar Cell Laser Scribing Machine With Auto Devide

Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H

Solar Cell Non-Destructive Laser Cutting Machine cuts solar cells into half pieces or 1/3 pieces ,which can increase the output of the solar panel power.

PV Laser Cutting Machine

6, how to make a half-cut solar module

first, we have to know how to make solar panels and half cell solar panels manufacturing process similar as traditional solar panels, from solar cell tabber stringer, Which can weld half-cut cell.

the manufacturing process is as follows:

Step 1 Solar Cell Testing, Test solar cells before welding from 156-210 Perc Mono or Poly, or IBC, TOPCON solar cells

Step 2 Solar Cell Cutting Cut solar cells to half 1/3 1/4 and more

Step 3 Solar Cell Welding & Tabbing, Tabbing solar cells to panel cell string

Step 4 Glass Loading and Solar EVA Film

Step 5 First EVA Layup

Step 6 Solar Stringer Lay Up Machine Layup, Solar Cell Strings Layup

Step 7 Solar Panel Interconnection Soldering Bussing Interconnection Soldering

Step 8 High-Temperature Taps, Taping

Step 9 EVA and Backsheet Films or Glass

Step 10Insulation Sheet For Half Cut Panel Isolated bus bar leads

Step 11 Solar Panel EL Defect Tester Visual Inspect & EL Defect Test

Step 12 Taping for Bifacial Solar Panels, double glass solar panels

Step 13 Solar Panel Laminating Laminat multiple layers of materials together

Step 14 Tearing Perforated Tape For Double Glass Panels

Step 15 Trimming

Step 16Flipping Inspection

Step 17 Solar Module Gluing & Framing & Loading

Step 18 Junction Box Installation AB Glue for Junction Box Potting

Step 20 Curing & Clean and Milling

Step 21 IV EL Testing & Insulation Hi-pot Testing

Step 22Solar Panel Sorting & Package

7, machines that make half-cut panels

half cell solar panels manufacturing machines almost the same as traditional silicon solar cells panels

half cut cells cutting machine

solar tabber stringer

solar string layup machine

online full auto EVA TPT cutting machine

8, can half-cut panels be made manually

To manufacture half cell modules, we can start from 1MW by manual,

9, full-auto produce line of hall-cut panels

to manufacture half cell modules, also can start from 30MW with full auto production lines

In the end,

welding half-cut solar cells from 156mm to 230mm

electric heating type and oil heating type available for all size solar cells