What Are the Core Points of a Tabber Stringer in Solar Panel Manufacturing?

Solar manufacturing success heavily depends on the precision and reliability of tabber stringer machines. As a solar production line expert with over 10 years of experience, I've seen how crucial this equipment is for quality panel production.

A tabber stringer is the cornerstone of solar panel assembly, responsible for connecting solar cells by precisely soldering copper ribbons. The quality of these connections directly impacts panel efficiency and long-term reliability.

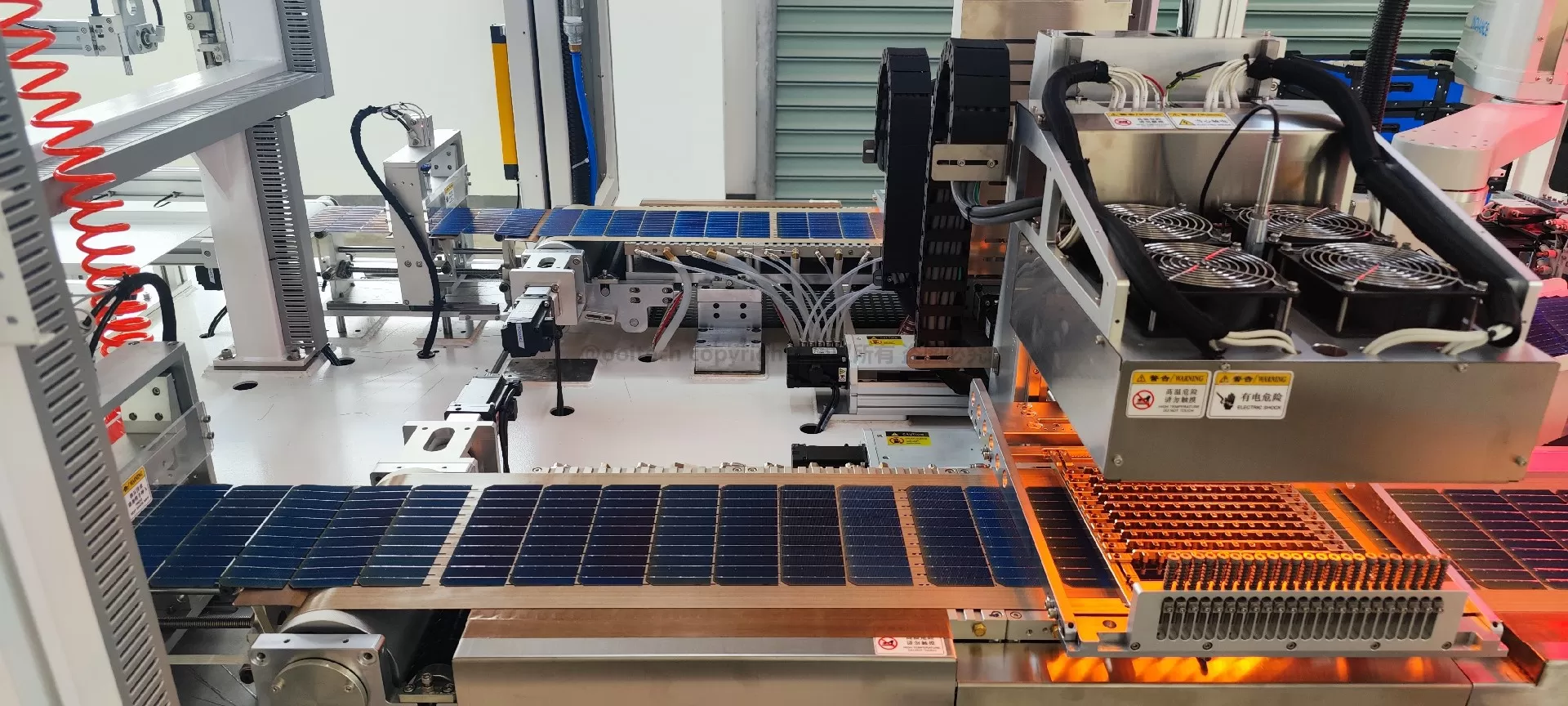

Latest generation tabber stringer machine with advanced control systems

What is the Role of a Tabber Stringer?

The primary function of a tabber stringer is to create reliable electrical connections between solar cells. This process is fundamental to solar panel manufacturing[1].

Modern tabber stringers automatically solder copper ribbons to solar cells, creating strings that form the basis of solar panels. The precision of this process directly affects panel efficiency and durability.

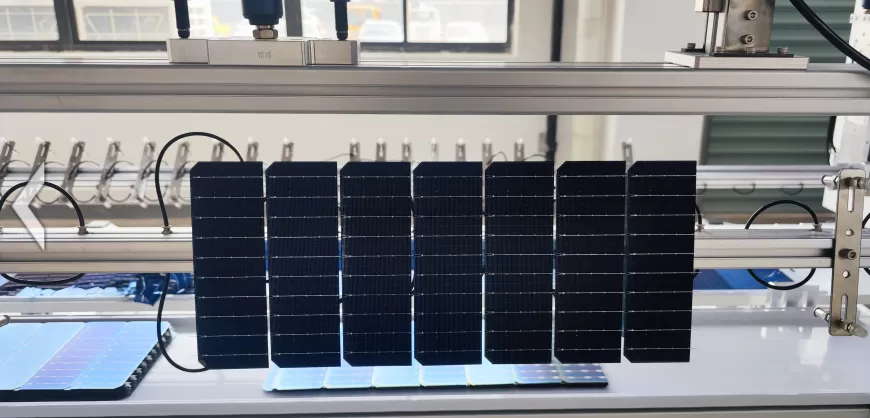

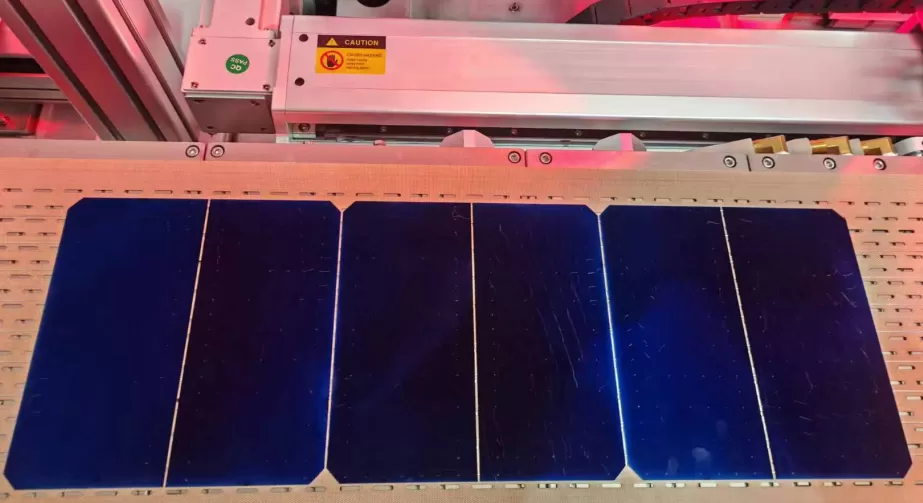

Detailed view of the tabbing and stringing process

Key Functions:

Pre-heating and flux application

Ribbon feeding and alignment

Precise temperature control

Cell positioning and transport

Quality inspection systems

| Process Step | Function | Quality Impact |

|---|---|---|

| Preheating | Temperature stabilization | Reduces thermal stress |

| Flux Application | Surface preparation | Ensures proper adhesion |

| Ribbon Feeding | Material delivery | Maintains consistent spacing |

| Soldering | Connection creation | Determines reliability |

| Cooling | Joint stabilization | Prevents deformation |

How Does Speed Affect Production Efficiency?

Production speed is a critical factor in manufacturing economics[2]. Modern tabber stringers can process up to 3,600 cells per hour, significantly impacting overall factory output.

The relationship between speed and quality requires careful balance. While higher speeds increase throughput, they must not compromise soldering quality or cell handling safety.

Advanced speed control interface for optimal production rate

Speed Optimization Factors:

Cell technology compatibility

Ribbon specifications

Soldering temperature requirements

Transport system capabilities

Quality control parameters

Which Welding Techniques Ensure Reliability?

Welding technique selection significantly impacts connection quality[3]. Modern systems employ advanced methods like infrared heating and induction soldering.

The choice between different welding technologies depends on cell type, ribbon specifications, and production requirements. Each method offers unique advantages for specific applications.

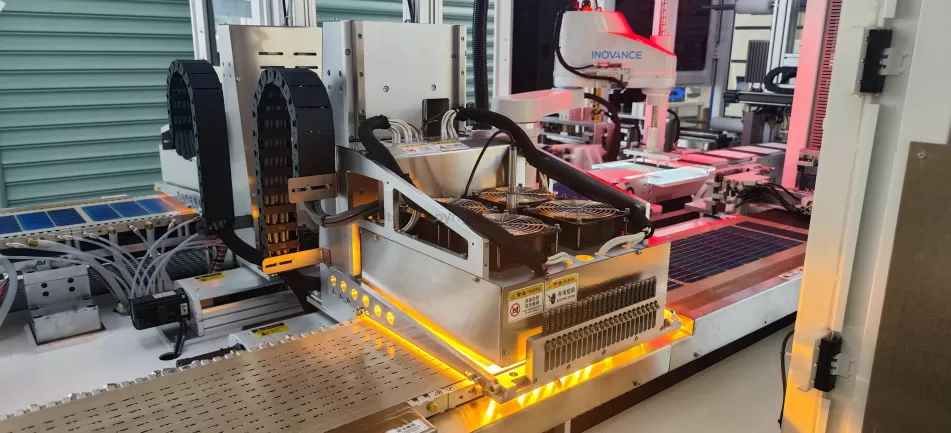

High-precision welding system with temperature monitoring

Comparison of Welding Methods:

| Method | Advantages | Considerations |

|---|---|---|

| Infrared | Precise control | Higher initial cost |

| Induction | Fast heating | Complex setup |

| Hot-air | Cost-effective | Speed limitations |

| Laser | High precision | Maintenance needs |

How to Evaluate Material Compatibility?

Material compatibility is crucial for long-term reliability[4]. The interaction between ribbons, soldering materials, and cell surfaces must be carefully evaluated.

Proper material selection ensures optimal electrical conductivity and mechanical strength while preventing degradation over time.

Advanced material testing equipment for quality assurance

Material Considerations:

Ribbon coating types

Flux compatibility

Cell surface properties

Temperature resistance

Mechanical stress tolerance

What Are Key Maintenance Considerations?

Regular maintenance is essential for consistent performance[5]. A well-maintained tabber stringer ensures high yield rates and minimal downtime.

Preventive maintenance schedules should include regular cleaning, calibration, and component inspection to prevent production interruptions.

Regular maintenance being performed on a tabber stringer

Critical Maintenance Points:

Transport system alignment

Heating element condition

Flux application system

Vision system calibration

Safety system verification

How to Improve Yield Rates with Tabber Stringers?

Yield optimization requires a comprehensive approach[6]. Modern tabber stringers incorporate advanced features for maximizing production efficiency.

Continuous monitoring and adjustment of process parameters, combined with proper operator training, can significantly improve yield rates.

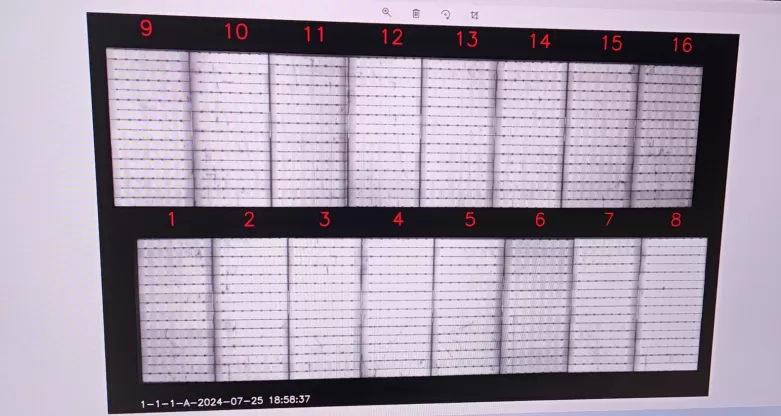

Real-time yield monitoring system interface

What's the MBB and BC All in One Tabber Stringer?

Multi Busbar (MBB) technology represents the latest advancement in solar cell interconnection[7]. Combined with Busbar-less Cell (BC) capabilities, these machines offer superior flexibility.

At Ooitech, we provide state-of-the-art MBB tabber stringers capable of handling both traditional and busbar-less cells, with production speeds up to 3,600 cells per hour.

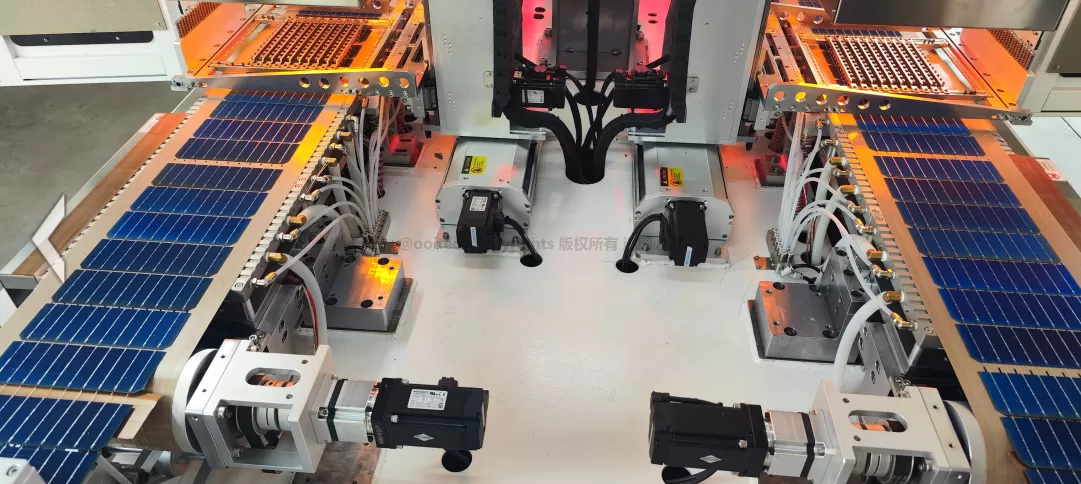

Advanced MBB tabber stringer with BC capability

Conclusion

Based on extensive industry experience, I strongly recommend investing in new tabber stringer equipment rather than second-hand machines. Ooitech offers comprehensive solutions including:

Full warranty coverage

Professional training programs

24/7 technical support

Spare parts availability

Regular maintenance services

For more information about our tabber stringer solutions, visit our YouTube channel or contact us at [email protected].