How Does a Solar Cell Laser Cutting Machine Enhance Module Production?

- What is the Role of Laser Cutting in Solar Production?

- How Does Laser Cutting Improve Precision?

- What Are the Benefits of Non-Contact Laser Cutting?

- How Does Laser Cutting Affect Production Efficiency?

- What Are the Key Technologies in Laser Cutting Machines?

- How to Avoid Purchasing Used Laser Cutting Machines?

- Ooitech's Solar Cell Laser Cutting Solutions

In today's competitive solar industry, manufacturers are constantly seeking ways to improve module efficiency and reduce production costs. The laser cutting machine has become a game-changing technology in solar cell processing.

Solar cell laser cutting machines use advanced laser technology to precisely cut solar cells into smaller segments, typically creating half-cut cells that increase module power output by 5-10% while reducing internal resistance losses.[1]

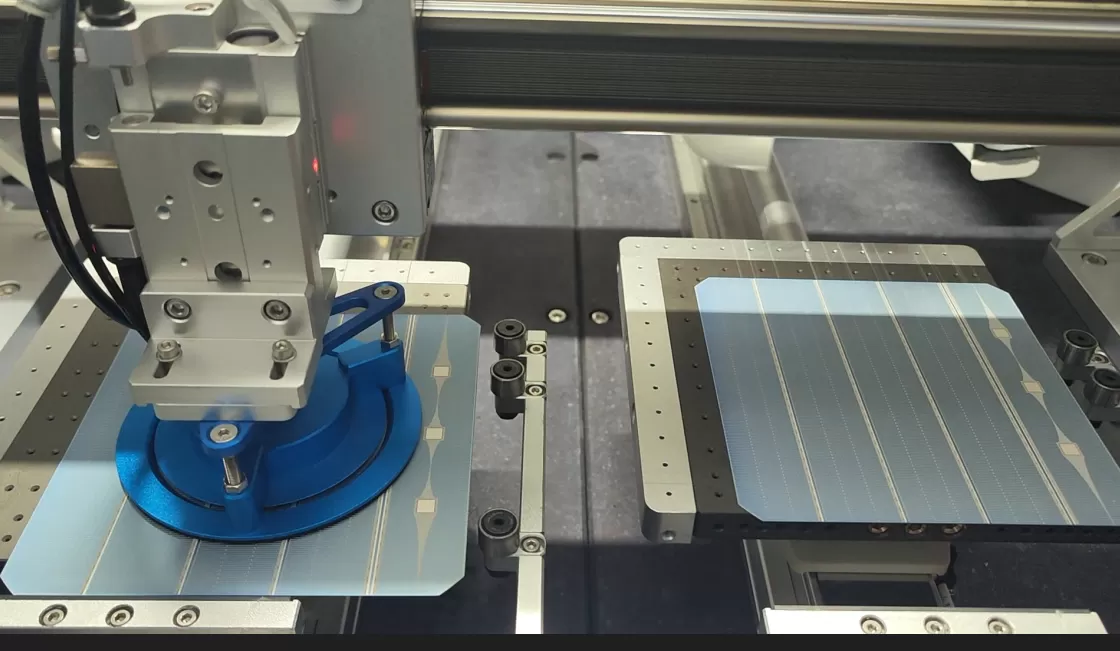

Modern solar cell laser cutting machine performing precision cuts

As a solar production line expert with over 10 years of experience, I've witnessed the remarkable evolution of laser cutting technology and its impact on module manufacturing.

What is the Role of Laser Cutting in Solar Production?

The solar industry's shift towards higher efficiency modules has made laser cutting an essential process. Half-cut cell technology, enabled by precise laser cutting, has become increasingly popular in modern solar module production.[2]

Laser cutting technology allows manufacturers to split standard solar cells into two or more parts, reducing internal resistance and improving overall module performance. This process is crucial for producing high-efficiency modules with power outputs exceeding 500W.[3]

Key Applications in Solar Manufacturing

| Application | Benefit | Typical Improvement |

|---|---|---|

| Half-cell cutting | Reduced resistive losses | 5-10% power gain |

| Edge isolation | Improved cell efficiency | 0.2-0.5% efficiency increase |

| Custom cell sizing | Flexible module design | Enhanced product variety |

How Does Laser Cutting Improve Precision?

Precision is paramount in solar cell processing, and laser cutting machines excel in this aspect. Modern laser cutting systems achieve cutting accuracies of ±0.1mm or better, which is essential for maintaining cell integrity.[4]

Laser cutting machines utilize advanced optical systems and precise motion control to achieve exceptional cutting accuracy. This precision ensures consistent cell quality and enables the production of high-efficiency half-cut cells.

High-precision laser beam cutting a solar cell

Precision Control Features

Advanced beam positioning systems

Real-time process monitoring

Automated quality control

Digital mapping and alignment

What Are the Benefits of Non-Contact Laser Cutting?

Unlike mechanical cutting methods, laser cutting is a non-contact process that eliminates physical stress on the solar cells.[5] This characteristic is particularly important as solar cells become thinner and more fragile.

Non-contact laser cutting significantly reduces cell breakage rates and microscopic damage, resulting in higher yield rates and better long-term module reliability.[6]

Advantages of Non-Contact Processing

| Feature | Traditional Cutting | Laser Cutting |

|---|---|---|

| Cell Contact | Direct physical contact | No physical contact |

| Stress on Cell | High mechanical stress | Minimal thermal stress |

| Edge Quality | Variable | Consistently smooth |

| Maintenance | Frequent blade replacement | Minimal maintenance |

How Does Laser Cutting Affect Production Efficiency?

Modern laser cutting machines can process thousands of cells per hour, significantly improving production throughput.[7] The automation capabilities of these machines reduce labor costs and increase consistency.

Advanced laser cutting systems can achieve processing speeds of up to 4,000 cells per hour, with some high-end machines capable of even higher throughput while maintaining precise cutting quality.[8]

Efficiency Metrics

Processing speed: 3,000-4,000 cells/hour

Automation level: 95-99%

Yield rate: >99%

Maintenance downtime: <5%

What Are the Key Technologies in Laser Cutting Machines?

Modern laser cutting machines incorporate several advanced technologies to ensure optimal performance and reliability.

The latest laser cutting systems feature high-power fiber lasers, precise motion control systems, and advanced software integration for Industry 4.0 compatibility.[9]

Core Technologies

Fiber laser sources (1064nm wavelength)

High-precision motion control

Advanced beam delivery systems

Real-time process monitoring

Automated material handling

How to Avoid Purchasing Used Laser Cutting Machines?

When investing in laser cutting equipment, it's crucial to avoid the pitfalls of purchasing used or refurbished machines that might compromise production quality.

New laser cutting machines offer superior reliability, updated technology, and comprehensive warranty coverage, making them a more cost-effective long-term investment.[10]

Verification Checklist

| Factor | New Machine | Used Machine |

|---|---|---|

| Warranty | Full coverage | Limited/None |

| Technology | Latest | Outdated |

| Support | Comprehensive | Limited |

| Efficiency | Optimal | Reduced |

| ROI | Higher | Lower |

Ooitech's Solar Cell Laser Cutting Solutions

At Ooitech, we specialize in providing state-of-the-art laser cutting machines for solar module production. Our equipment is designed to meet the demanding requirements of modern solar manufacturing.

For detailed information about our laser cutting solutions, visit www.ooitech.com or watch our production line demonstration on our YouTube channel.

Conclusion

Laser cutting technology has become indispensable in modern solar module production. As the industry continues to advance towards higher efficiency modules, the role of precise, automated laser cutting becomes increasingly crucial. Ooitech remains committed to providing cutting-edge solutions that help manufacturers achieve their production goals.

For more information about our solar production line solutions, contact us at [email protected] or via WhatsApp at +8615961592660.