Research on the standardization of N-type TOPCon cells

- updated: 2023-05-14

- By

ooitech

- visits: 26347

- 0

In recent years, with the development and utilization of new technologies, new processes and new structures of photovoltaic cells, the photovoltaic cell industry has developed rapidly. As a key technology supporting the development of new energy and smart grids, n-type cells have become a hot spot in global industrial development.

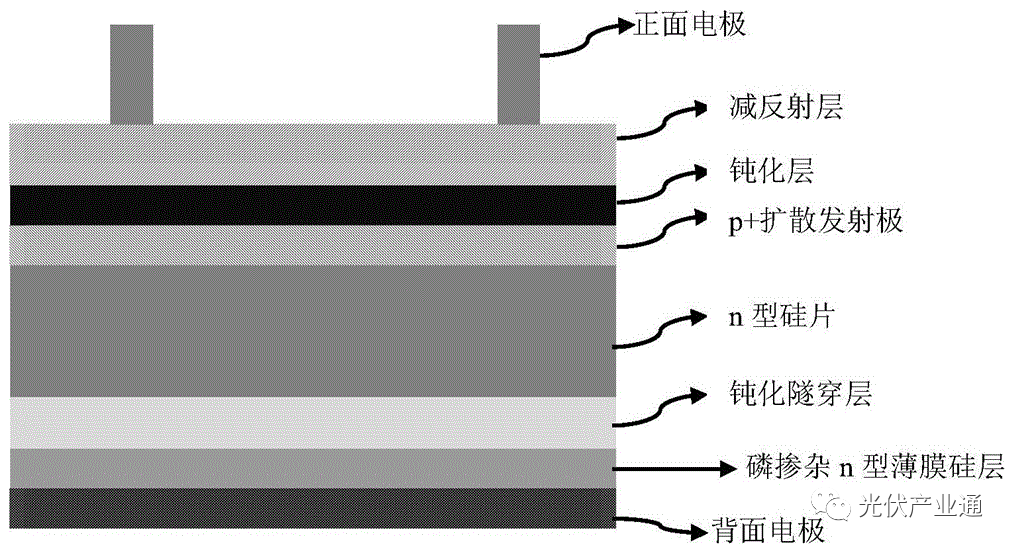

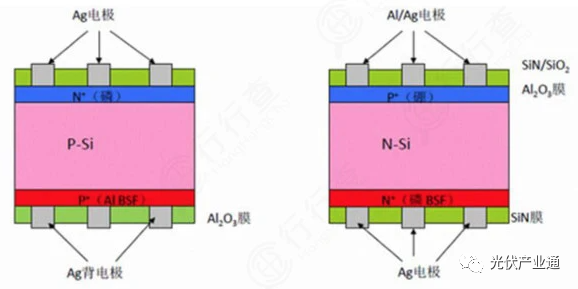

Because the n-type tunneling oxide layer passivation contact photovoltaic cell (hereinafter referred to as "n-type TOPCon cell") has the performance advantage of significantly improving efficiency compared with conventional photovoltaic cells, with the increase in cost controllable and mature equipment transformation, the n-type TOPCon cell Further expansion of domestic production capacity has become the main development direction of high-efficiency photovoltaic cells. The standardization of n-type TOPCon batteries faces problems such as the inability to cover current standards and the need to improve the applicability of standards. This paper will conduct research and analysis on the standardization of n-type TOPCon batteries, and give suggestions for standardization.Development status of n-type TOPCon cell technologyThe structure of p-type silicon base material used in conventional photovoltaic cells is n+pp+, the light-receiving surface is n+ surface, and phosphorous diffusion is used to form the emitter.There are two main types of homojunction photovoltaic cell structures for n-type silicon base materials, one is n+np+, and the other is p+nn+.Compared with p-type silicon, n-type silicon has better minority carrier lifetime, lower attenuation, and greater efficiency potential.The n-type double-sided cell made of n-type silicon has the advantages of high efficiency, good low light response, low temperature coefficient, and more double-sided power generation.As the industry's requirements for photoelectric conversion efficiency of photovoltaic cells continue to increase, n-type high-efficiency photovoltaic cells such as TOPCon, HJT, and IBC will gradually occupy the future market.According to the 2021 International Photovoltaic Roadmap (ITRPV) global photovoltaic industry technology and market forecast, n-type cells represent the future technology and market development direction of photovoltaic cells at home and abroad.Among the technical routes of the three types of n-type batteries, n-type TOPCon batteries have become the technology route with the largest industrialization scale due to their advantages of high utilization rate of existing equipment and high conversion efficiency.

The standardization of n-type TOPCon batteries faces problems such as the inability to cover current standards and the need to improve the applicability of standards. This paper will conduct research and analysis on the standardization of n-type TOPCon batteries, and give suggestions for standardization.Development status of n-type TOPCon cell technologyThe structure of p-type silicon base material used in conventional photovoltaic cells is n+pp+, the light-receiving surface is n+ surface, and phosphorous diffusion is used to form the emitter.There are two main types of homojunction photovoltaic cell structures for n-type silicon base materials, one is n+np+, and the other is p+nn+.Compared with p-type silicon, n-type silicon has better minority carrier lifetime, lower attenuation, and greater efficiency potential.The n-type double-sided cell made of n-type silicon has the advantages of high efficiency, good low light response, low temperature coefficient, and more double-sided power generation.As the industry's requirements for photoelectric conversion efficiency of photovoltaic cells continue to increase, n-type high-efficiency photovoltaic cells such as TOPCon, HJT, and IBC will gradually occupy the future market.According to the 2021 International Photovoltaic Roadmap (ITRPV) global photovoltaic industry technology and market forecast, n-type cells represent the future technology and market development direction of photovoltaic cells at home and abroad.Among the technical routes of the three types of n-type batteries, n-type TOPCon batteries have become the technology route with the largest industrialization scale due to their advantages of high utilization rate of existing equipment and high conversion efficiency. At present, n-type TOPCon batteries in the industry are generally prepared based on LPCVD (low-pressure vapor-phase chemical deposition) technology, which has many procedures, efficiency and yield are restricted, and equipment relies on imports. It needs to be improved. The large-scale production of n-type TOPCon cells faces technical difficulties such as high manufacturing cost, complicated process, low yield rate, and insufficient conversion efficiency.The industry has made many attempts to improve the technology of n-type TOPCon cells. Among them, the in-situ doped polysilicon layer technology is applied in the single-process deposition of tunneling oxide layer and doped polysilicon (n+-polySi) layer without wrapping plating;The metal electrode of the n-type TOPCon battery is prepared by using the new technology of mixing aluminum paste and silver paste, which reduces the cost and improves the contact resistance; adopts the front selective emitter structure and the back multi-layer tunneling passivation contact structure technology.These technological upgrades and process optimization have made certain contributions to the industrialization of n-type TOPCon cells.Research on standardization of n-type TOPCon batteryThere are some technical differences between n-type TOPCon cells and conventional p-type photovoltaic cells, and the judgment of photovoltaic cells in the market is based on the current conventional battery standards, and there is no clear standard requirement for n-type photovoltaic cells.The n-type TOPCon cell has the characteristics of low attenuation, low temperature coefficient, high efficiency, high bifacial coefficient, high opening voltage, etc. It is different from conventional photovoltaic cells in terms of standards.

At present, n-type TOPCon batteries in the industry are generally prepared based on LPCVD (low-pressure vapor-phase chemical deposition) technology, which has many procedures, efficiency and yield are restricted, and equipment relies on imports. It needs to be improved. The large-scale production of n-type TOPCon cells faces technical difficulties such as high manufacturing cost, complicated process, low yield rate, and insufficient conversion efficiency.The industry has made many attempts to improve the technology of n-type TOPCon cells. Among them, the in-situ doped polysilicon layer technology is applied in the single-process deposition of tunneling oxide layer and doped polysilicon (n+-polySi) layer without wrapping plating;The metal electrode of the n-type TOPCon battery is prepared by using the new technology of mixing aluminum paste and silver paste, which reduces the cost and improves the contact resistance; adopts the front selective emitter structure and the back multi-layer tunneling passivation contact structure technology.These technological upgrades and process optimization have made certain contributions to the industrialization of n-type TOPCon cells.Research on standardization of n-type TOPCon batteryThere are some technical differences between n-type TOPCon cells and conventional p-type photovoltaic cells, and the judgment of photovoltaic cells in the market is based on the current conventional battery standards, and there is no clear standard requirement for n-type photovoltaic cells.The n-type TOPCon cell has the characteristics of low attenuation, low temperature coefficient, high efficiency, high bifacial coefficient, high opening voltage, etc. It is different from conventional photovoltaic cells in terms of standards.

This section will start from the determination of the standard indicators of the n-type TOPCon battery, carry out corresponding verification around the curvature, electrode tensile strength, reliability, and initial light-induced attenuation performance, and discuss the verification results.Determination of standard indicatorsConventional photovoltaic cells are based on the product standard GB/T29195-2012 "General Specifications for Ground-Used Crystalline Silicon Solar Cells", which clearly requires the characteristic parameters of photovoltaic cells.Based on the requirements of GB/T29195-2012, combined with the technical characteristics of n-type TOPCon batteries, the analysis was carried out item by item.See Table 1, n-type TOPCon batteries are basically the same as conventional batteries in terms of size and appearance;

Table 1 Comparison between n-type TOPCon battery and GB/T29195-2012 requirements

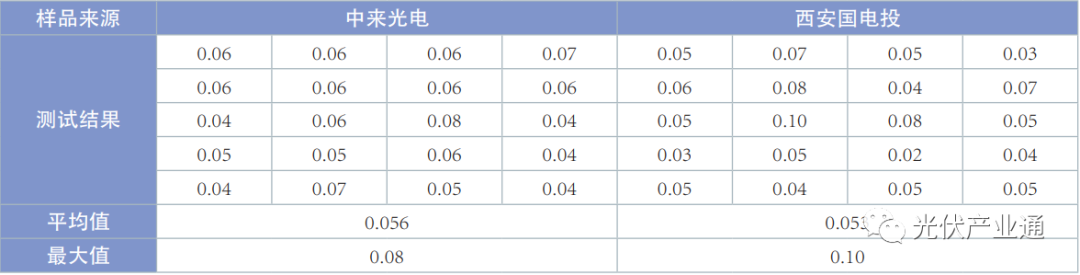

In terms of electrical performance parameters and temperature coefficient, tests are carried out according to IEC60904-1 and IEC61853-2, and the test methods are consistent with conventional batteries; the requirements for mechanical properties are different from conventional batteries in terms of bending degree and electrode tensile strength.In addition, according to the actual application environment of the product, a damp heat test is added as a reliability requirement.Based on the above analysis, experiments were carried out to verify the mechanical properties and reliability of n-type TOPCon batteries.Photovoltaic cell products from different manufacturers with the same technical route were selected as experimental samples. The samples were provided by Taizhou Jolywood Optoelectronics Technology Co., Ltd.The experiment was carried out in third-party laboratories and enterprise laboratories, and the parameters such as bending degree and electrode tensile strength, thermal cycle test and damp heat test, and initial light-induced attenuation performance were tested and verified.Verification of Mechanical Properties of Photovoltaic CellsThe bending degree and electrode tensile strength in the mechanical properties of n-type TOPCon batteries are directly tested on the battery sheet itself, and the verification of the test method is as follows.Curvature refers to the deviation between the center point of the median surface of the tested sample and the reference plane of the median surface. It is an important indicator to evaluate the flatness of the battery under stress by testing the bending deformation of the photovoltaic cell.Its primary test method is to measure the distance from the center of the wafer to a reference plane using a low pressure displacement indicator.Jolywood Optoelectronics and Xi'an State Power Investment provided 20 pieces of M10 size n-type TOPCon batteries each. The flatness of the surface was better than 0.01mm, and the battery curvature was tested with a measuring tool with a resolution better than 0.01mm.The battery bending test is carried out according to the provisions of 4.2.1 in GB/T29195-2012.The test results are shown in Table 2.

Table 2 Bending test results of n-type TOPCon cells

The enterprise internal control standards of Jolywood and Xi’an State Power Investment both require that the bending degree is not higher than 0.1mm. According to the analysis of the sampling test results, the average bending degree of Jolywood Optoelectronics and Xi’an State Power Investment is 0.056mm and 0.053mm respectively. The maximum values are 0.08mm and 0.10mm, respectively.According to the results of the test verification, the requirement that the curvature of the n-type TOPCon battery is not higher than 0.1mm is proposed.Electrode tensile strength test verificationThe metal ribbon is connected to the grid wire of the photovoltaic cell by welding to conduct current. The solder ribbon and the electrode should be connected stably to minimize the contact resistance and ensure the current conduction efficiency.For this reason, the electrode tensile strength test on the grid wire of the battery can evaluate the electrode weldability and welding quality of the battery, which is a common test method for the adhesion strength of the photovoltaic battery motor.<section style="margin: 0px 0px 16px;padding: 0px;outline