Overview of LPCVD and PECVD Technologies in Photovoltaic Cell Manufacturing

Overview of LPCVD and PECVD Technologies in Photovoltaic Cell Manufacturing

The manufacturing of photovoltaic (PV) cells involves a variety of thin-film deposition techniques, among which Low Pressure Chemical Vapor Deposition (LPCVD) and Plasma Enhanced Chemical Vapor Deposition (PECVD) are two critical methods. These technologies play a significant role in determining the performance, efficiency, and reliability of solar cells, making them essential components of modern photovoltaic manufacturing processes.

LPCVD Technology

LPCVD is a deposition technique characterized by its operation at low pressure, which provides several advantages over other methods. The LPCVD system typically comprises various components including a temperature control system, quartz tube, loading and unloading mechanisms, vacuum and pressure control systems, flow and temperature control systems, safety protection systems, and a computer control unit.

1. Advantages of LPCVD:

Uniform Film Thickness: One of the primary advantages of LPCVD is its ability to produce films with excellent uniformity. At lower pressures, the reactive gases are evenly distributed, ensuring a consistent deposition across the substrate. This characteristic is vital in reducing variations in film thickness and composition, which can adversely affect the performance of the final product.

Precise Temperature Control: LPCVD allows for deposition at relatively low temperatures, minimizing thermal damage to sensitive substrates. This precision is especially important when manufacturing delicate semiconductor devices that may be adversely affected by high temperatures.

Controlled Film Properties: The properties of the deposited films can be finely tuned by adjusting various parameters such as the type of reactive gases, pressure, temperature, and deposition time. This capability enables manufacturers to customize the thickness, density, and resistivity of the films to meet specific application requirements.

Compatibility with Existing Processes: LPCVD is highly compatible with existing semiconductor manufacturing processes, allowing for seamless integration into current production lines. This compatibility is crucial for manufacturers looking to upgrade or expand their capabilities without significant investment in new equipment.

LPCVD is commonly used to deposit materials such as silicon, silicon nitride, and silicon dioxide, which are critical in the fabrication of integrated circuits. These thin films serve various functions, including isolation layers, protective layers, and electrodes. Furthermore, LPCVD technology finds extensive application in the production of Poly layers for TopCon (Tunnel Oxide Passivated Contact) solar cells. Its excellent step coverage capability allows for a one-stop solution for the preparation of tunneling oxide layers and Poly layers, thereby significantly enhancing production capacity and reducing equipment costs.

PECVD Technology

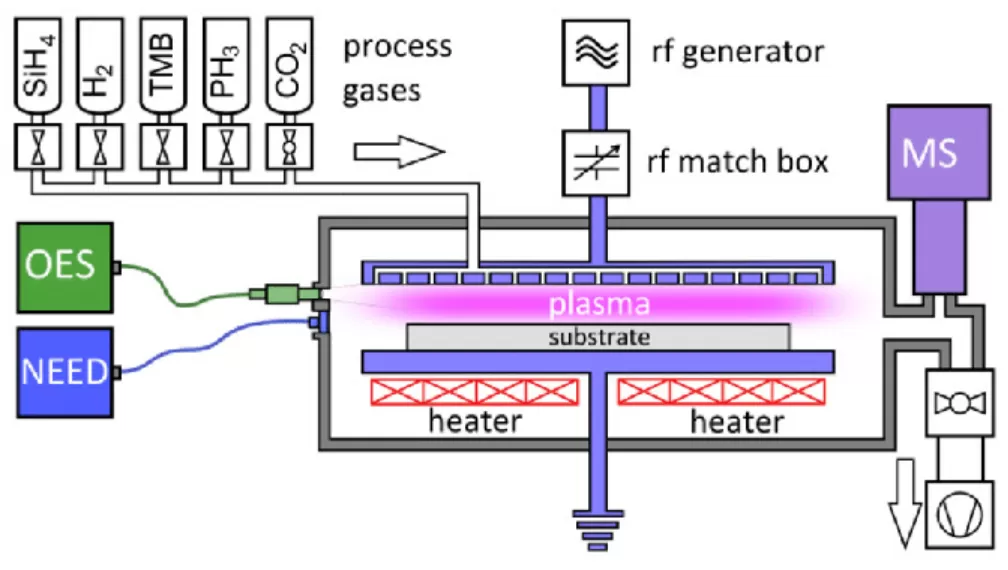

PECVD is another widely utilized thin-film deposition technology in the semiconductor manufacturing and microfabrication sectors. The PECVD process involves several key steps, including the activation of precursor gases, plasma formation, and film deposition.

1. Process Overview:

Reactive Gases: The process begins with the introduction of gases containing the desired film materials into the reaction chamber. These gases serve as precursors and undergo chemical reactions once activated.

Plasma Activation: Using a radio frequency (RF) power source or other plasma excitation methods, the reactive gases are converted into a plasma state. The high-energy active species present in the plasma facilitate the chemical reactions necessary for film formation.

Film Deposition: Under plasma activation conditions, the film material is deposited on the substrate surface. The resulting films exhibit specific properties, such as conductivity, insulation, or optical characteristics, depending on the precursor gases and processing parameters used.

Process Control: PECVD allows for precise control of deposition parameters such as gas flow rates, plasma power, temperature, and pressure. This control is crucial for adjusting the film thickness, composition, and properties to meet specific requirements.

2. Advantages of PECVD:

Low-Temperature Deposition: One of the most significant advantages of PECVD is its ability to deposit films at low temperatures. This characteristic is particularly beneficial for substrates that require high thermal stability, minimizing the risk of damage during the deposition process.

High Purity and Uniformity: PECVD can produce thin films with high purity and excellent uniformity. This quality is essential for applications where film integrity is critical, such as in photovoltaic cells.

Versatile Material Deposition: PECVD is suitable for depositing a variety of materials, including SiO2, Si3N4, and Al2O3, among others. This versatility makes it applicable in various photovoltaic cell manufacturing processes, including PERC (Passivated Emitter and Rear Cell), TOPCON, and HJT (Heterojunction Technology).

Conclusion

Both LPCVD and PECVD technologies play pivotal roles in the manufacturing of photovoltaic cells. Their unique characteristics and advantages enable the production of high-performance, efficient solar cells. As technology continues to evolve, these deposition methods are expected to undergo further advancements, enhancing their capabilities and supporting the growth of the photovoltaic industry. Consequently, the integration of LPCVD and PECVD into PV cell manufacturing processes not only contributes to improving solar cell efficiency but also helps to meet the increasing global demand for renewable energy solutions.